Fecralloy Metal Fiber Fabric

Key Features:

1: Fast response due to low thermal inertia

2: Thermal & mechanical shock resistance

3: Homogenous combustion

4: High modulation capability

5: Flashback safety

6: High temperature corrosion resistance

Product Description:

What is Fecralloy Metal Fiber Fabric?

Fecralloy Metal Fiber Fabric is made of fecralloy metal fiber yarn. It has two types: woven fiber fabric and kintted fiber fabric. It is used on metal fiber burners, boilers and also used as high temperature buffering material. Fecralloy Metal Fiber Fabric gives almost limitless potential to construct burners of all shapes and sizes. It also has the function of combustion supporting, energy conservation and emission reduction. We can manufacture customized metal fiber fabric with almost unlimited diversity of size and shape.

Fecralloy Metal Fiber Fabric Properties:

1: Fast response due to low thermal inertia

2: Thermal & mechanical shock resistance

3: Homogenous combustion

4: High modulation capability

5: Flashback safety

6: High temperature corrosion resistance

7: From a 10cm square burner heat output can vary from 1 to 20kW.

8: Max working temperature upto 1100℃

9: Long working life in high temerature

Fecralloy Metal Fiber Fabric Applications:

1: Flue and gas filtering ,

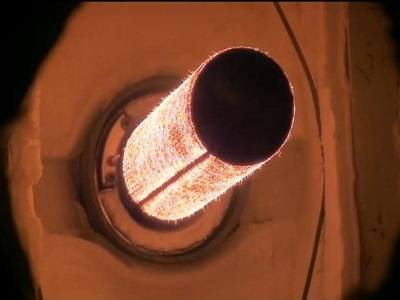

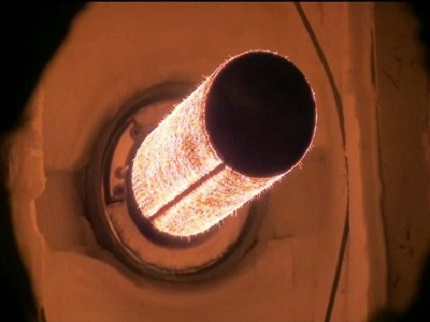

2: Infrared gas burner,

3: Gas heating burner part,

4: Combustion supporting for gas burning boiler, oil burning boiler and coking plants,

5: High temperature buffering material for producing automotive glass, solar PV glass and electronic components.

Metal fiber fabric fabrication methods and difference:

Metal fiber fabric made by knitting: good softness, good ductility, resilient

Fiber fabric made by weaving: good softness, high strength, better solidity(not easy to change shape).

Fecralloy Metal Fiber fabric commonly used specifications:

| Fabrication methods | Weight (g/Sq.m) | Thickness(mm) | Width(mm) |

| Woven | 1560 | 1.6 | 1000 |

| Woven | 2000 | 2 | 1000 |

| Knitted | 790 | 2.3 | 1000 |

| Knitted | 1130 | 3.2 | 1000 |

| Knitted | 2100 | 3.8 | 1000 |