Hastelloy X Mesh

Key Features:

1. Outstanding corrosion resistance in reducing environments

2. High strength maintained at the elevated temperatures

3. Mesh Size: 0.2mesh/inch to 300mesh/inch

4. Wire Dia: 0.03mm to 8.0mm

Technical Data Mesh Specification ChartsProduct Description:

Hastelloy X Mesh (UNS N06002) offers suitable strength, oxidation resistance and welding properties at temperatures about 2200oF. It is specifically fit for use in reducing and neutral conditions providing sustained ductility at the high temperatures. It controls stress corrosion cracking in the petrochemical applications and is used in gas turbine engine combustors, heat processing devices, flame holders, furnace components, aircraft and marine engineering.

Hastelloy X Mesh Applications:

Filtration, ultrahigh filters, screening, vents, chemical plants, catalyst support systems for pyrolysis operations, ideal for furnace applications as it provides outstanding resistance to oxidizing and reducing conditions.

Hastelloy X – Super Alloy:

Hastelloy X is one of the popular nickel alloy steels. As compare to other alloys of similar composition, Hastelloy X prevents an attack of strong chemicals and offers supreme high temperature strength. This is the reason that this alloy is chosen for use in the numerous applications in energy, medical, environment, oil & gas and flue gas desulfurization industries.

Hastelloy X Mesh Chemistry:

| Ni | Mo | Cr | Fe | W | Co | Mn | C | P | S | Si | Al | Ti | B | Cu |

| Bal | 8-10 % | 20.5 – 23 % | 17 – 20 % | 0.2 – 1 % | 0.5 – 2.5 % | 1 % | 0.05 – 0.15 % | 0.04 % | 0.03 % | 1 % | 0.50 % | 0.15 % | 0.01 % | 0.50 % |

Hastelloy X Mesh Property Data:

| Specifications | ASTM B572, AMS 5798, AWS A5.14 |

| Density | 0.297 lbs per cubic inch |

| Tensile Strength | 118 Kpsi |

| Elongation | 42% |

| Melting temperature | 2470 oF |

| Highest service Temperature | 2200 oF |

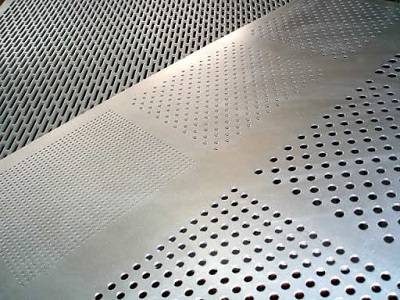

Hastelloy X Mesh Available Types:

| Woven Wire Mesh | Expanded Metal | Perforated Metal | Further fabricated mesh products |