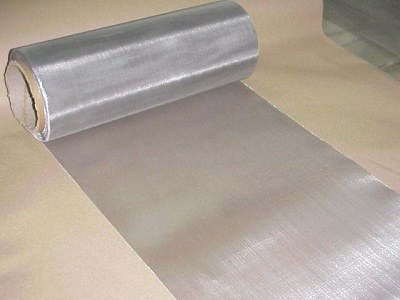

Inconel X750 Mesh

Key Features:

1. High temperature oxidation resistance up to 1300of

2. Good stability and resistance to SCC

3. Mesh Size: 0.2mesh/inch to 300mesh/inch

4. Wire dia: 0.03mm to 8.0mm

Technical Data Mesh Specification ChartsProduct Description:

Inconel X750 Mesh (UNS N07750) provides fine resistance to corrosion and oxidation in addition of high tensile and creeping strength up to 1300oF. Inconel X750 has similar composition to alloy 600 with additional contents of aluminum and titanium. It is a precipitation hardenable alloy providing great relaxation resistance when utilized in the elevated temperature operations.

Applications of Inconel X750 Mesh

Aerospace and aircraft engineering, pollution control, high temperature fluid filtration

Inconel X-750 Mesh chemistry:

| C | Mn | Si | Cu | S | Ni +Co | Cr | Ti | Fe | Al | Nb + Ta |

| 0.08 % | 0.30 % | 0.50 % | 0.50 % | 0.01 % | 70 % | 14 – 17 % | 2.25 – 2.70 % | 5 – 9 % | 0.40 – 1 % | 0.70 – 1.20 % |

Inconel X-750 Mesh Property Data

| Specifications | ASTM B637, AWS A.5.14 |

| Density | 0.298 lbs/in³ |

| Tensile Strength | 125 Kpsi |

| Elongation | 40 % |

| Melting temeprature | 2540 oF |

| Highest service temperature | 1300 oF |

| Coefficient of Thermal Expansion | 12.6 μm/m.oC at 20oC to 100oC or 7.0×10-6 in/in.oF |

| Modulus of Rigidity | 75.8 kN/mm2 or 10994 ksi |

| Modulus of elasticity | 218.0 kN/mm2 or 31619 ksi |

| 212.4 kN/mm2 or 30806 ksi | |

| 213.7 kN/mm2 or 30995 ksi | |

| Thermal conductivity | 117 Btu-in/ft²-hr-°F or 16.9 W/m-K at 300of or 149oC |

Inconel X-750 Mesh Available Types:

| Woven Wire Mesh | Expanded Metal | Perforated Metal | Further fabricated mesh products |