Nichrome 80 Mesh

Key Features:

- Oxidation and permeability resistance

- Low temperature coefficient of electric resistance

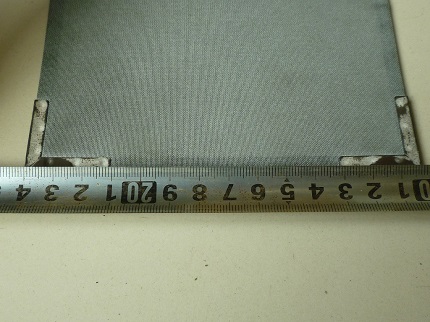

- Mesh Size: 0.2mesh/inch to 300mesh/inch

- Wire Dia: 0.04mm to 8.0mm

Technical Data Mesh Specification Charts

Product Description:

What is Nichrome 80 mesh?

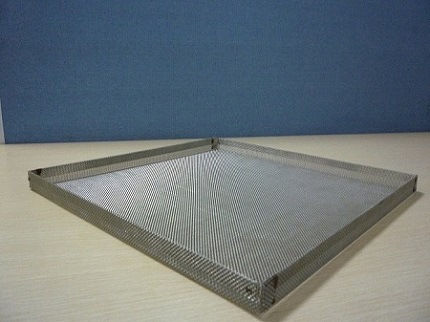

Nichrome 80 mesh is made by weaving high quality nichrome 80 wire. Nichrome 80 mesh contains 80% of nickel and 20% of chrome. Nichrome 80 mesh is availabe in rolls, customized sheets and further manufactured Mesh Trays and Baskets.The mesh tray and baskets are used for sintering and heat treatment. Nichrome 80 mesh has outstanding tensile strength, oxidation resistance and corrosion resistance properties in high temperature applications.

Heanjia Super Metals Co., Ltd. is leading manufacturer of Nichrome 80 mesh products since 1984.

Nichrome 80 Mesh offers properties such as deformation resistance, thermal stability, mechanical strength and shockproof ability at high temperatures. While heating, it also shows stable performance in air.

Nichrome 80 mesh is widely used in heat treatment plans, air carbon furnace belts, electronick component sintering plans, chemical plants as well as metallurgy.

Why Nichrome as a Mesh?

Nichrome Mesh has a key role in the heat processing for electronic components. It offers many advantages including deformation resistance, thermal stability, mechanical strength, shock resistance in the heated state and oxidation resistance. Nichrome is the best fit material in the heating applications as it produces an adherent layer of chromium oxide that prevents further corrosion in the hot air hence securing the beneath metal from burning or fracturing.

Nichrome Mesh Available specifications:

Mesh: 0.2mesh to 300mesh

Wire dia: 0.05mm to 8.0mm

Mesh width: up to 5000mm

Nichrome Mesh Tray Specifications: customized sizes available, please contact with us for more information.

Nichrome 80 Mesh Chemistry Component:

| Nickel | Chromium |

| 80 % | 20 % |

Nichrome 80 Mesh Property Data:

| Density | 8.31 gram per cubic cm |

| Electrical resistivity | 108 microhm • cm at 20oC |

| 650 ohm. Circ. Mil/ft at 20oC | |

| Highest service temperature | 300oC or 572oF |

| Melting temperature | 1400oC or 2550oF |

| Coefficient of thermal expansion | 12.5 micro-m per m oC from 20oC to 100oC |