High temperature belts for service in the vigorous media

Over the decades the plants have been forced to use conveyor belts that are sensitive to damages specially under the high temperature environments. This causes frequent system shutdown, clean-up and high maintenance costs.

Overall what we need is the better quality belt.

With the research and development processes conducted over the century, the belt is made with latest structure, offering sturdiness under the wide temperature limits up to 750oF or 400oC. Heanjia Super-Metals offer you a supreme quality abrasion resistant belts that serve in the vigorous application conditions.

Applications that demand heat and abrasion resistance, splice adhesion characteristics have been increasing such as cement plants, kilns, foundries, oven plants, iron pellets and others. So for durable service in such applications, you need a reliable belt.

Latest manufacturing that withstands at high temperatures up to 750oF or 400oC

We develop the belts that resist hardening and fracturing while handling the fine or tough loads at the elevated points. The lab tests describe that in the high heat media, the belts retain tensile strength. Enhanced cover service under the wide heat increases the belt life while reducing the material carry-back. Maintenance costs related with early cracking and blistering are widely diminished.

The belts prevent the cupping and curling tendency of typical high temperature belts permit supreme belt tracks and reduced edge damage.

Supreme abrasion resistance under wide conditions

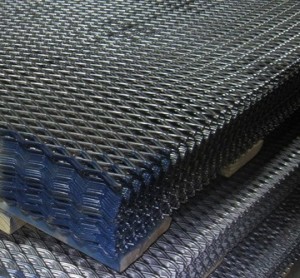

As compare to traditional belts, our Hastelloy wire mesh belts prevent the edge damage and offer safe service. They quality the abrasion tests and offer significantly long service in the different high temperature media. These benefits offer you a great peace of mind and good return on investment.

Heanjia’s belt prevent the need of mechanical splices, permitting you to get the benefit of belt cleaners and additionally decrease the cost cycle related with the material maintenance and clean-up.

Traditional high-heat belts are usually slit from wider rolls. Therefore it is uncommon for belts to have camber, needing more time to practice in the beginning. The belts are made to width with molded edges therefore you never receive a hooked belt. They are good to go from the moment they are installed. They continue to serve exceptionally in the applications.

The wide heat technology strength begins at the core. The carcass is developed from proprietary mesh and dipping that prevent delamination and flexural fatigue.

Choosing the suitable heat resistant belt

The surface temperature of the belt changes with the type and size material being conducted. The large holes allow air distribution keeping the belt surface cool.

In choosing a belt, it is essential to determine the application temperature and also the surface temperature the belt will serve at.

We are here to offer the high temperature conveyor belts made from nichrome wire mesh and other materials. The belts are made in the different weights and widths, available for several uses, typically for service from – 100oF to 2100oF. These are designed for use in the hot end processing applications in the industries such as plastics, automotive, food processing, metal casting and others.