How important is Mesh Strainer Structure and its Types

The woven wire mesh cloth should not be associated with perforations that relate to perforated sheet metals. The mesh screens offer smaller size wye pattern strainers and are not fit for heavy duty strainers if not paired with perforated metal screen. The mesh clothes are basically used for ultra fine straining as they have fine holes that cannot be received with perforated metal.

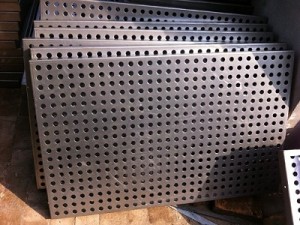

On the other hand, a heavy dusty perforated metal screen has big perforations and lined

with wire mesh cloth. It may not be applicable in small size strainers where the lighter wire meshes offer suitable performance. The meshes are made perfectly fit for self alignment.

The use of strainers made from stainless steel mesh ensures the complete security of the mechanical device from the adverse effects of dirt, scale, and foreign materials. They are specifically made for prolong performance in the corrosive, high pressure and elevated temperature applications. The straight structure prevents the corrosion of the strainer hence allowing it to serve for long while preventing the vast damage of the threads. Durable structure with fine mesh prevents the particle clogging, the strainers are usually configured above of most of equipments to secure them from damage caused by big contaminants.

Structure

The flow clean strainer is constituted of a heavy monel wire mesh screen covered with fine monel mesh outer cloth. Both of these elements are safely soldered. The structure is designed to avoid the passage of foreign particles of fine size. It is specifically perfect for particles of algae, wood pulp, roots etc. Made in the different sizes, the flow clean strainer performs by following the velocity principle and implements air foil concept for self cleaning. Particle impingement occurs only on the leading edge. The small pressure region on the downstream part of the mesh avoids the clogging of contaminants. The scouring action resulted by eddy currents maintains the cleanliness of the screen. Install the strainer in a pipe unit that has a moving flow to keep it tidy.

The compact design of strainer for the pipeline flanges. It is used for safety during commissioning and commencement of the new equipments. It is economical and lightweight.

Strainer Types

- The element is a core of a eaton strainer. Once the strainer housing is chosen, same attention should be given to a screen design and the mesh size or perforation, as this describes the eventual performance of the device.

- The cylindrical strainers comprise of a standard basket with bow shaped handles that are moved down to confirm a tight seal in the strainer. This type of strainer is made from hastelloy wire mesh or stainless steel mesh.

- Pleated type baskets have a nominal pressure drop. The pleated structure offers a larger straining region.

Screens are used in auto – cleaning strainers rather of baskets to store the unnecessary particles as well as debris. These materials are made so that the debris removed easily during backwashing. The screens are constructed from perforated plate, sintered wire mesh and wedge wire.