Product Description:

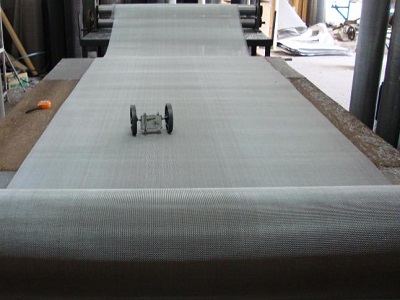

Wire Mesh Calendaring– we can calendar material up to 700mm wide. This is available in either sheets or coils. Calendaring helps to control product thickness and insures a dead flat product.

Calendaring is used to finish woven wire cloth by flattening the cloth. Its main benefit is to help control the thickness of the wire cloth, ensuring a precise and uniform material thickness.

The benefits of calendaring include:

- Uniform material thickness of the cloth due to the flattening process

- Flat, even surface to the wire mesh

- Increased strength to the cloth as the crimps are locked together

- Increased stability to the cloth due to a tighter link between wires and crimps

- Stabilizes the edges and helps prevent loose edge wires from falling out.

Flattening and Stretching of Wire Mesh– Material up to 60” wide can be flattened and stretched to stabilize the mesh and improve the overall quality of the wire cloth part.

We offer flattening and shaping services for woven wire mesh and welded wire mesh. As with many steel products, wire mesh and welded wire mesh have coil set or memory in the material after welding or weaving. These products will need to be processed to make the material flat, level and ready for production. We can help you solve the problems with coil set, camber or side curl in your wire cloth or mesh.