Tungsten Mesh

Key Features:

- Smooth and clean mesh surface

- Stable service at the high temperatures

- Exceptional corrosion resistance

- Very high melting point

Product Description:

What is Tungsten mesh?

Tungsten Mesh is made by weaving pure tungsten wire. Tungsten Mesh offers excellent high temperature mechanical characteristics and smallest coefficient of thermal expansion among all metals. It is used in the elevated temperature filtration applications. It has supreme thermal creeping resistance and maximum service temperature up to 3400oC. Tungsten mesh is extremely durable.

Tungsten Mesh Available Specifications:

Wire diameter: 0.03mm to 2mm

Opening size: 0.1mm to 25mm.

Sheet size: width up to 2000mm, no limit to length

Note: small samples of several sizes are available for testing purpose

Tungsten Mesh Applications:

Chemical industries, acid production, scientific research labs and universities, filter, vacuum apparatus, hydrogen production, fire hazard security and heat shielding.

Tungsten Mesh Property Data:

| Atomic No. | 74 |

| Melting Point | 3695 K or 3422oC or 6192oF |

| Boiling Point | 6203 K or 5930 oC or 10706 oF |

| Density | 19.25 g/cm3 |

| Thermal expansion | 4.5 µm/ (m.K) at 25oC |

| Thermal conductivity | 173 W/m.K |

| Electrical resistivity | 52.8 nΩ.m at 20oC |

| Young Modulus | 411 GPa |

| Shear Modulus | 161 GPa |

| Poisson Ratio | 0.28 |

| Vickers Hardness | 3430 to 4600 MPa |

| Brinell Hardness | 2000 to 4000 MPa |

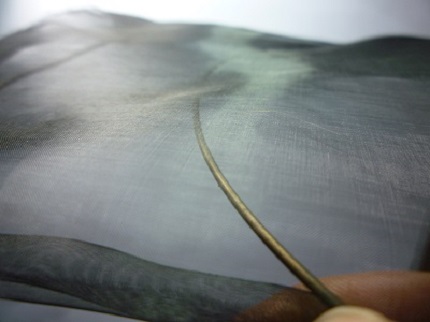

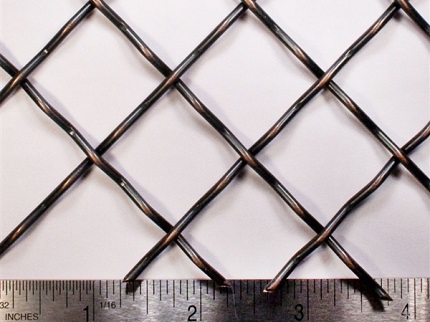

Tungsten Mesh Product Photos: