Hastelloy Mesh

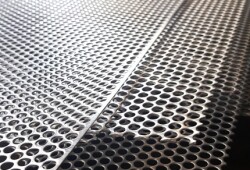

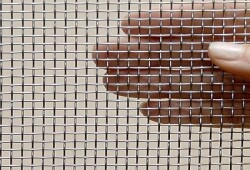

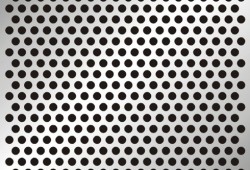

We produce hastelloy Mesh, hastelloy Wire Mesh and hastelloy Perforated Metal. They are made of high quality hastelloy materials. We manufacture the mesh with customized specifications. Our most popular product is Hastelloy C276 Mesh.

Hastelloy meshes are proven as excellent product for applications in elevated temperature and chemical corrosive environments. They have supreme durability, good strength and high pressure and stress tolerance. Hastelloy wire mesh and hastelloy perforated metal are widely used in heat exchangers, extrusion equipment, vibration reduction andchemical industry filtrations.

Hastelloy wire Mesh and hastelloy perforated metal are made of various grades of Hastelloy alloys depending on the application. The commonly used grade is Hastelloy C276. It offers excellent resistance to pitting and crevice corrosion, chloride and sulfur induced stress corrosion cracking and aqueous corrosion.

We manufacture hastelloy mesh that meet different technical requirements for different applications. Our factory has been in wire mesh industry for over 30 years. As the first factory that focus on manufacturing nickel mesh and nickel alloy mesh in the wire mesh industry, our company has win high reputation for suppling best quality products.

Please feel free to contact with us and tell us your needs, let us produce a consistent, accurate, reliable and precise mesh for you.