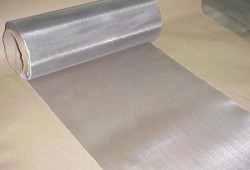

Stainless Steel Mesh

Heanjia produce Stainless steel mesh in a wide range of grades and specifications for use in industries. The stainless steels include SS 304, SS 310, SS 316, SS 321, SS330, SS904L, etc.

The applications are:

1. Marine

2. Pharmaceuticals

3. Food Preparation

4. Rubber and Plastic

5. Aerospace Engineering

6. Automotive

7. Oil and refineries

8. General industries

9. Chemical Plants

Stainless steel mesh has supreme oxidation resistance and is also easy to fabricate. It can be formed and cut to size with suitable tools and machinery.

Stainless steel mesh offers exceptional corrosion resistance and has ability to prevent pitting and crevice attack in hot chloride solutions. They are recommended for use in various of industrial applications.