Nichrome Mesh

Heanjia Super Metals Co., Ltd. supplies Various of Nichrome Mesh products, we have Nichrome Wire Mesh and Nichrome Mesh Tray and Sintering Basket for electronic parts heat treatment. Heanjia has many years of experience in manufacturing Nichrome mesh products. Nichrome Mesh is made of Nichrome 80 or Nichrome 60. It has wide applications in heat treatment and other high temperature environments. Upon exposure to air, the mesh forms an adherent oxide layer that prevents oxidation of the beneath metal.

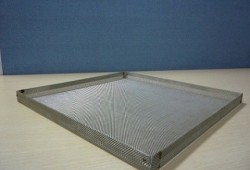

Nichrome Mesh Tray is widely used for Electronic Parts Sintering Procedures. The Nichrome mesh tray is made of USA/EU imported material and made with advanced technique. It can work for long time without deforming nor breaking in high temperature, as high as 1250oC.

There are several considerable factors that decide mesh performance; please get in touch with our team who will help you in choosing the best Nichrome mesh product for your unique requirements. We will fully assist you in designing the perfect mesh product.