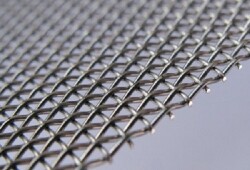

FeCrAl/Kanthal Mesh

Heanjia Super Metals Co., Ltd. supplies common FeCrAl Mesh, Super Fecral alloy(Kanthal) mesh, FeCrAl Fiber Mat, and Fecral alloy Fiber Fabric.

Super Fecral Alloy Mesh is made of a special grade of Fecral alloy, it is made by the same technique with Kanthal: powder-metallurgical and dispersion-strengthened technique. It can serve in extremely high temperature up to 1400oC with long serving life. The resistance to high temperature heating makes Super Fecral alloy Mesh good for use in high temperature furnaces and heat processing elements.

The common FeCrAl Mesh is made of alloys such as 0Cr25Al5, 0Cr23Al5. It is widely used on gas burner, tail gas treatment device and other high temperature applications.

FeCrAl (Fecralloy) Fiber Mat/Fiber Fabric is used on metal fiber burners, such as radiant burners and gas infrared burners. It is suitable for use over a wide range up to 1100°C. FeCrAl (Fecralloy) fiber mat has longer high temperature life, having greater oxidation resistance and form stability over other alloys.