Monel, Copper Nickel Mesh

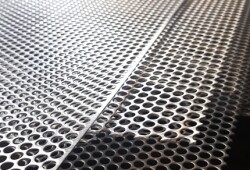

Heanjia Super Metals Co., Ltd. supplies Monel Mesh, it mainly include Monel 400 Mesh, Monel K500 Mesh and Copper Nickel alloy Mesh (Cu70Ni30/Cu90Ni10). The product forms include woven screen, perforated metal, expanded metal and sintered mesh.

Customers can choose any alloy, mesh type and specification upon their application requirement.

Monel Mesh offers excellent resistance to seawater and steam from low to elevated temperatures. Monel Mesh is also resistant to rapidly flowing brackish water, scc, hydrochloric acid and hydrofluoric acid in the deaerated conditions. It is widely used in sea water applications, chemical and hydrocarbon processing systems.

Monel Mesh is widely used in marine applications such as:

Marine facilities

Seawater filter and desalination

Waste water treatment

Filtering decontaminate

Heat processing