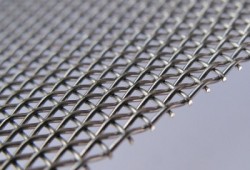

Super Duplex Stainless Steel Mesh

Heanjia Super Metals Co., Ltd. is professional manufacturer of Super Duplex Stainless Steel Mesh. The products are Super Duplex 2205 Mesh, Super Duplex 2250 Mesh and Super Duplex 2207 Mesh. Super Duplex Stainless Steel Mesh is highly durable. It retains its structure in the vigorous application environments. They have outstanding corrosion resistance and high strength. They also offer exceptional resistance to pitting, crevice, erosion and general corrosion in aggressive conditions.

Heanjia is the largest super duplex steel mesh manufacturers and suppliers in China. Our product are known for good material quality, sturdy mesh construction and dimensional accuracy.

Please feel free to contact with us for more information.