Product Description:

Heanjia offers PVC, Teflon and epoxy coating services for wire mesh products.

PVC Coated Wire Mesh: PVC coating adds extra value to this wire panel. Customized colors Available, the PVC coating creates a clean look for your application while the coating prevents cuts and other injuries.

PVC Coated Wire Mesh Characteristics:

1: Strong & light with a high ware value,

2: Clean appearance will not flake or chip

3: Corrosion-resistant

4: Water-resistant

Common Applications for PVC Coated Wire Mesh:

- Industrial security

- Animal cages and enclosures

- Kennel flooring

- Lobster traps

- Oyster trays

- Tennis courts

- Home and garden fencing

- Marine fencing

- Freeway fencing

- Machine guards

PTFE (Teflon) Coated Wire Mesh:

PTFE coating provide additional strength to the mesh as well as protecting the mesh from contaminants during use. PTFE coated products enhance the performance of filtration systems, particularly for industrial cartridge filters.

PTFE (Teflon) coating can be done perfectly to fully coat the strands of the woven mesh without filling in the apertures. Most woven mesh used for this method of filtration is either 100 or 200 mesh size, manufactured from stainless steel wire threads.

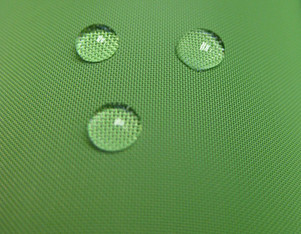

When surface materials are coated with PTFE, water droplets rest on the surface, without actually wetting to any significant extent. PTFE (Teflon®) coatings are used to increase the hydrophobic performance of the filter, by means of permitting fuels to pass through but inhibit the passage of water in coalescer based systems. In such systems the PTFE coated mesh can be easily cleaned during maintenance and service operations. It has been found that PTFE coated mesh filters can help to reduce operating costs and improve product quality.

Industrial Applications of PTFE Coated Wire Mesh:

1: Chemicals, Resins and Solvents

2: Hydraulic Oils

3: Petroleum Refining

4: Power Generation

5: Pulp and Paper Industry

6: Fuel Lines

Epoxy Coated Wire Mesh:

Epoxy coating add stability to small diameter wire mesh products to improve their performance. These coatings are used mainly for filters and screens.