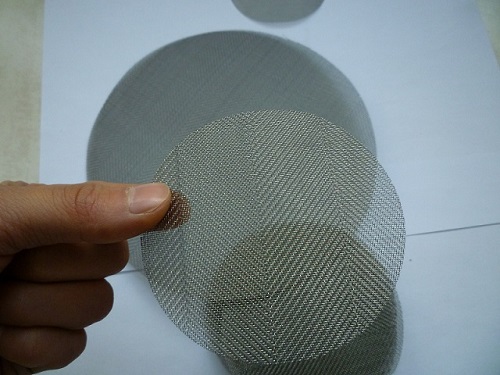

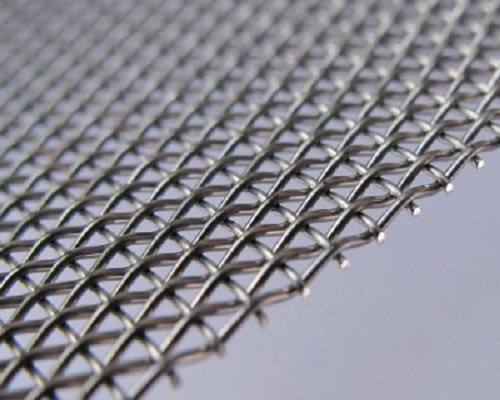

FeCrAl Mesh

Key Features:

- Outstanding heat and carburization resistance

- Low temperature coefficient of electric resistivity

- Mesh Size: 0.2mesh/inch to 300mesh/inch

- Wire Dia: 0.07mm to 8.0mm

Product Description:

FeCrAl Mesh is made of fecral alloys such as 0Cr25Al5, 0Cr23Al5, Kanthal D, Kanthal A-1, etc. It offers excellent heat resistance and prevents oxidation and corrosion in high temperature and high pressure conditions. FeCrAl Mesh is commonly utilized for heating and drying operations. Customers can choose the fecral alloy grade depending on the working temperature and other conditions.

Fecral alloys’ Highest Working Temperatures:

| Alloy | Temperature |

| Cr21Al4 | 1100oC |

| Cr21Al6 | 1250oC |

| Cr23Al5 | 1250oC |

| Cr25Al5 | 1250oC |

| Kanthal D | 1200oC |

| Kanthal A-1 | 1350oC |

Properties of FeCrAl Mesh/Kanthal Mesh:

- Excellent heat resistance

- Prevents oxidation and sulfur based corrosion

- Anti-carburization

- Large surface load bearing

- High strength and durable

- Low temperature coefficient of resistance

Applications of FeCrAl Mesh/Kanthal Mesh:

FeCrAl Mesh is primarily utilized as drying and heating devices in metallurgy, industrial electric furnace, gas burners and infrared equipments and heaters.

For your diversed application requirements, our heating mesh in various sizes provide excellent performance to become your preferred product. Contact us to discover how we have become the pioneer industrial mesh vendor since 1984.