Hastelloy Perforated Metal

Key Features:

- High corrosion resistance in chemicals

- Prevent localized and uniform corrosion

- Using high quality Hastelloy sheets

- Available in different hole sizes, pitches, sheet sizes and thickness.

Product Description:

Hastelloy perforated metal is one of our best selling products. We can produce it according to customer requirements. It is available in different hole sizes, pitches, sheet sizes and thickness.

Hastelloy C276 perforated metal is the most commonly used Hastelloy grade. It is well known for providing excellent resistance to local and uniform corrosion and combined industrial chemicals including strong oxidizers, for example: cupric and ferric chlorides, chlorine, hot contaminated solutions such as organic and inorganic, acetic anhydride, acetic acids, formic and marine water, brine water and reducing agents. Therefore Hastelloy perforated metal fit for use in the severe industrial chemical corrosive media. They are used in chemical screens, separators, filters, strainers etc.

Hastelloy C276 Perforated Metal Chemical Composition:

| Element | Mo | Cr | Fe | W | Co | C | Si | Mn | V | P | S | Ni |

| Min(%) | 15.0 | 14.5 | 4.0 | 3.0 | — | — | — | — | — | — | — | — |

| Max(%) | 17.0 | 16.5 | 7.0 | 4.5 | 2.5 | 0.01 | 0.08 | 1 | 0.35 | 0.04 | 0.03 | Rem |

Hastelloy C276 Perforated Metal Property Data:

| Density | 0.321 lb./in.(3) at 72℉ or 8.89 g/cm(3) at 22℃ |

| Melting Point | 2415 to 2500 or 1323 to 1371 |

| Electrical Resistivity | 51 microhm/in. at 75℉ or 1.30 microhm/m at 24℃ |

| Modulus of elasticity | 29.8 Psi or 205 GPa |

| Coefficient of thermal expansion | 6.2 microin./in.-°F or 11.2 x10 (-6) m/m-K at 75 to 200℉ or 24 to93℃ |

| Thermal conductivity | 71 Btu-in/ft²-hr-°F or 10.2 W/m-K at100℉ or 38℃ |

| Ultimate tensile strength | 100.8 Ksi or 695 MPa |

| Yield strength at 0.2 % offset | 42.1 ksi or 290 Mpa (heat processed at 2050℉, rapid cooling) |

| Elongation % in 2 inch | 56 |

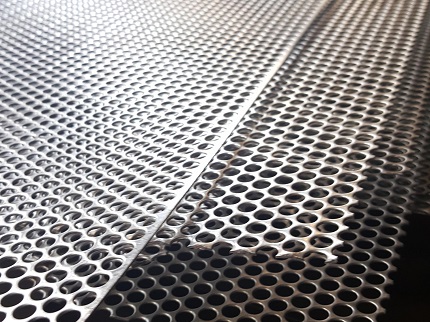

Pictures of Hastelloy Perforated Metal: