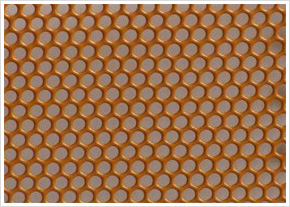

Copper Nickel Alloy Mesh 90/10

Key Features:

- Resistance to biofouling and soil erosion

- High mechanical strength and EMI shielding properties

- Mesh Size: 0.2mesh/inch to 300mesh/inch

- Wire Dia: 0.03mm to 8.0mm

Product Description:

Copper-nickel alloy mesh made from Cu90Ni10 (UNS C70600) is a widely used material, particularly known for its excellent performance in marine and other corrosive environments. This alloy is the most common grade of copper-nickel used for seawater service due to its cost-effectiveness and exceptional combination of properties.

Copper Nickel Alloy Mesh Available Size Range:

Wire diameter: 0.05mm to 8mm

Opening size: 0.05mm to 30mm

Sheet size: width up to 5000mm, no limit on length.

Chemical Composition:

The designation Cu90Ni10 indicates its primary composition of approximately 90% copper and 10% nickel. Like the 70/30 alloy, it includes small but crucial additions of other elements to enhance its performance:

- Copper: 85.6 – 90%

- Nickel: 9.0 – 11.0%

- Iron: 1.0 – 1.8%

- Manganese: up to 1.0%

The controlled additions of iron and manganese are vital for this alloy’s superior corrosion and erosion resistance in seawater. They help to form a protective film that prevents pitting and crevice corrosion.

Key Properties:

The properties of Cu90Ni10 (UNS C70600) make it a top choice for a wide range of applications:

- Excellent Corrosion Resistance: It provides outstanding resistance to general corrosion, pitting, and crevice corrosion in saltwater, brackish water, and other hostile environments.

- High Resistance to Biofouling: The copper content in the alloy inhibits the growth of marine organisms like barnacles and algae, making it an excellent choice for seawater intake screens and other submerged applications.

- Good Strength and Ductility: While not as strong as the 70/30 alloy, it still offers good tensile and yield strength for many applications. It is also highly ductile, meaning it can be easily formed into a variety of mesh weaves and configurations.

- Good Weldability: Cu90Ni10 is known for its excellent welding and fabrication properties, making it easy to create complex structures and assemblies.

- Thermal and Electrical Conductivity: It maintains a higher thermal and electrical conductivity than the 70/30 alloy, which can be an advantage in certain heat exchanger and electrical applications.

Applications

The unique combination of properties makes Cu90Ni10 wire mesh a popular material for various industries, including:

- Marine and Offshore:

- Seawater Intake Screens: A primary application where the mesh prevents marine debris and organisms from entering cooling and fire water systems.

- Condenser and Heat Exchanger Components: Used in marine vessels, power plants, and desalination facilities for its corrosion resistance and heat transfer properties.

- Piping Systems: Used in saltwater piping on ships and offshore platforms.

- Desalination Plants: Used in various components of desalination systems where resistance to hot, corrosive seawater is critical.

- Chemical and Petrochemical Industries: The mesh is used for filtration and separation in processes involving corrosive fluids.

- Architecture and Art: Due to its reddish-gold color and durability, it can be used for decorative purposes, especially in coastal or maritime-themed installations.

Mesh Weave Types:

Cu90Ni10 wire mesh is available in common weave types to meet different requirements:

- Plain Weave: Suitable for general filtration, sieving, and screening applications.

- Twilled Weave: Provides a denser, stronger mesh for more demanding filtration needs.

- Dutch Weave: Used for fine filtration of small particles.

- Welded Mesh: Used for structural and heavy-duty applications like grates and industrial screens.

+1 206 890 7337

+1 206 890 7337 sales1@nickel-wiremesh.com

sales1@nickel-wiremesh.com