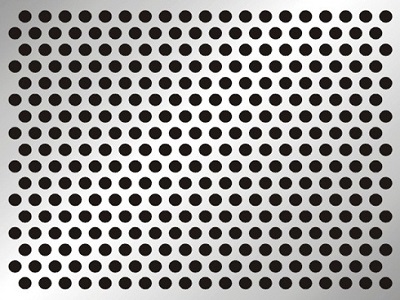

Copper Nickel Alloy Perforated Metal

Key Features:

- Outstanding Corrosion Resistance

- Biofouling Resistance

- Good Strength and Ductility

- Aesthetic Appeal

- Versatility of Patterns

Technical Data Mesh Specification Charts

Product Description:

Copper-nickel (cupronickel) alloy perforated metal is a type of sheet metal that has been mechanically punched with a series of holes, slots, or other decorative patterns. This material is highly valued for combining the excellent properties of copper-nickel alloys with the functional benefits of perforated metal.

Copper-nickel (cupronickel) alloy perforated metal Key Characteristics

The primary grades used for perforated metal are the same as those for wire mesh:

- Cu90Ni10 (UNS C70600): The most common grade for seawater service due to its excellent corrosion and biofouling resistance, along with good weldability.

- Cu70Ni30 (UNS C71500): A stronger alloy with superior resistance to erosion and impingement corrosion, making it suitable for more aggressive environments.

The key characteristics of copper-nickel perforated metal include:

- Outstanding Corrosion Resistance: Cupronickel alloys are renowned for their ability to resist corrosion in seawater, brackish water, and various industrial fluids. The perforated form maintains this resistance, even at the edges of the holes.

- Biofouling Resistance: The copper content naturally inhibits the growth of marine organisms, which is a major advantage for submerged applications like screens and filters. This prevents blockages and reduces maintenance costs.

- Good Strength and Ductility: The alloys are strong enough for structural applications while being ductile enough to be easily formed and perforated without cracking.

- Aesthetic Appeal: The silver-like appearance of copper-nickel, combined with intricate perforation patterns, makes it an attractive choice for architectural and decorative applications.

- Versatility of Patterns: Perforated metal can be manufactured with a wide variety of hole shapes (round, square, slotted, etc.) and patterns (staggered, straight), allowing for a high degree of customization to meet specific functional or design requirements.

Specification of Copper Nickel Alloy Perforated Sheet:

We can manufacture a wide range of metal sheets with thickness varying from 0.35mm to 8.0mm and width maximum 2000mm. Length is the overall measurement of the long side of the sheet and width is the measurement of short side of the sheet. The standard sheet size is 1200mm*2400mm and 1000mm*2500mm.

Applications

The unique properties of perforated copper-nickel make it a preferred material for applications in demanding industries:

- Marine and Offshore:

- Seawater Filters and Strainers: The most common use, where the perforated sheets prevent marine debris from entering cooling systems on ships, offshore platforms, and desalination plants.

- Architectural Screens and Cladding: Used on coastal buildings and marine structures for both its durability and its aesthetic appeal.

- Marine Fencing and Barriers: Provides a strong, corrosion-resistant barrier that can also resist biofouling.

- Filtration and Separation:

- Used as screens and sieves for filtering liquids and solids in chemical and petrochemical plants. The corrosion resistance ensures the material’s longevity and prevents contamination.

- Architecture and Design:

- Façade and Decorative Panels: Perforated copper-nickel can be used for building exteriors and interiors to control light, air flow, and for its unique appearance.

- Acoustic Panels: The perforations allow for sound absorption, making it suitable for soundproofing applications.

- General Industrial Use:

- Machine guards, ventilation screens, and protective panels in corrosive industrial environments.

- Basket and tray components in processes that involve corrosive chemicals.

+1 206 890 7337

+1 206 890 7337 sales1@nickel-wiremesh.com

sales1@nickel-wiremesh.com