Monel Mesh

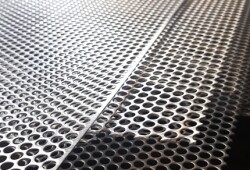

Heanjia Super Metals Co., Ltd. supplies Monel Mesh, it mainly include Monel 400 Mesh and Monel K500 Mesh. The product forms include woven screen, perforated metal, expanded metal and sintered mesh.

Monel mesh is a premium nickel-copper alloy (primarily Ni 63-70%, Cu 27-34%) wire mesh known for exceptional corrosion resistance, high strength, and durability in extreme environments. It outperforms stainless steel in many aggressive chemical and marine applications.

🔹 Key Mesh Grades comparison:

| Grade | Composition | Key Properties | Best For |

| Monel 400 mesh (UNS N04400) | 63-70% Ni, 27-34% Cu + Fe/Mn | Excellent corrosion resistance | marine & chemical industries |

| Monel K500 Mesh (UNS N05500) | Ni-Cu + Al/Ti (precipitation-hardened) | Excellent corrosion resistance, Higher strength | aerospace & deep-sea applications |

| 90/10 Cu-Ni Mesh (C70600) | 90% Cu, 10% Ni, <1% Fe/Mn | Superior seawater corrosion resistance, good weldability | Marine, desalination, condensers |

| 70/30 Cu-Ni Mesh (C71500) | 70% Cu, 30% Ni, <1% Fe/Mn | Superior strength, higher corrosion resistance than 90/10 | Offshore oil & gas, chemical processing |

| 66/30/2/2 Cu-Ni (C71640) | 66% Cu, 30% Ni, 2% Fe, 2% Mn | Enhanced erosion resistance | High-flow seawater systems |

🔹 Key Properties & Advantages:

Monel 400 and K500: Excellent Corrosion Resistance

- Resists seawater, sulfuric/hydrochloric acid, alkalis, and hydrofluoric acid (better than stainless steel).

- Immune to chloride stress corrosion cracking (SCC).

✔ High Strength & Toughness - Retains strength at cryogenic to 550°C temperatures.

- Monel K500 has twice the yield strength of Monel 400.

✔ Excellent Fabrication Properties - Can be welded, brazed, and soldered easily.

✔ Biofouling & Erosion Resistance - Ideal for marine filters, offshore platforms, and desalination plants.

Copper Nickel Alloy: Cu90/Ni10, Cu70/Ni30:

✔ Superior Corrosion Resistance

– Resists seawater, sulfuric acid, chloride, and biofouling (better than stainless steel in some marine environments).

✔ Excellent Thermal Conductivity

– Used in heat exchangers, condensers, and HVAC systems.

✔ Antimicrobial & Biofouling Resistance

– Copper ions inhibit algae/bacterial growth (ideal for marine and medical filters).

✔ Good Weldability & Formability

– Easily fabricated into custom mesh shapes.

✔ High Ductility & Fatigue Resistance

– Performs well in vibrating or high-stress environments.

🔹 Common Weave Types & Specifications

- Plain Weave (Most Common)

– Balanced grid for filtration, sieving, and shielding.

– Mesh Sizes: 0.2 to 200 mesh.

– Wire Diameters: 0.05mm to 5mm.

- Twilled Weave

– Stronger, denser weave for high-pressure filtration.

- Dutch Weave (Micron-Level Filtration)

– Fine mesh for filtering small particles in corrosive liquids.

- Welded Mesh (Structural Use)

– Used in marine grates, architectural facades, and industrial screens.

🔹 Top Applications

✅ Marine & Offshore

– Seawater intake screens, boat hulls, desalination plants (resists biofouling).

– Offshore oil rigs (resists sulfide corrosion).

✅ Chemical & Petrochemical

– Acid filtration, refinery screens, heat exchangers.

✅ Power & HVAC

– Condenser tubes, cooling water systems.

✅ Medical & Food Processing

– Antimicrobial filters, hygienic processing screens.

✅ Architectural & Decorative

– Anti-corrosive facades, artistic mesh panels.

+1 206 890 7337

+1 206 890 7337 sales1@nickel-wiremesh.com

sales1@nickel-wiremesh.com