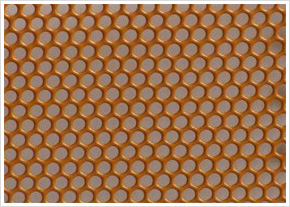

Copper Nickel Alloy Mesh 70/30

Key Features:

- Prevents attack of soil erosion and corrosion in seawater

- Resistance to tarnish and oxidation

- Mesh Size: 0.2mesh/inch to 300mesh/inch

- Wire Dia: 0.03mm to 8.0mm

Product Description:

Copper-nickel alloy mesh made from Cu70Ni30 (UNS C71500) is a high-performance material valued for its exceptional properties, particularly its superior resistance to corrosion and erosion in demanding environments. This alloy is a step up from the more common 90/10 copper-nickel (C70600) and is chosen for applications where greater strength and durability are required.

Copper Nickel Alloy Mesh Available Size Range:

Wire diameter: 0.05mm to 8mm

Opening size: 0.05mm to 30mm

Sheet size: width up to 5000mm, no limit on length.

Chemical Composition

The designation Cu70Ni30 signifies its primary composition: approximately 70% copper and 30% nickel. It also includes key additions of other elements to enhance its performance:

- Nickel: 29.0 – 33.0%

- Iron: 0.40 – 1.0%

- Manganese: up to 1.0%

- Copper: Remainder (typically 65% minimum)

The iron and manganese additions are particularly important, as they contribute significantly to the alloy’s resistance to general corrosion, erosion, and impingement corrosion caused by high-velocity water.

Key Properties

The chemical composition gives Cu70Ni30 wire mesh a number of critical properties:

- Superior Corrosion Resistance: It offers outstanding resistance to corrosion in seawater, brackish water, and other corrosive fluids. It also performs well in environments with hot, de-aerated seawater.

- High Erosion Resistance: This alloy is more resistant to erosion and impingement attack than the 90/10 alloy, making it suitable for applications with high flow rates and turbulence.

- Excellent Strength: Cu70Ni30 has higher tensile and yield strength compared to the 90/10 grade, which makes it more durable and capable of withstanding higher pressures and stresses.

- Biofouling Resistance: Like other copper-nickel alloys, it has inherent resistance to macro-fouling, which is the accumulation of marine organisms like barnacles and algae.

- Good Thermal and Electrical Conductivity: While not as conductive as pure copper, it retains enough conductivity to be useful in certain heat exchange and electrical applications.

- Fabricability: The alloy has good cold and hot working capacity, and can be easily welded, brazed, or soldered.

Applications

The combination of strength, corrosion resistance, and erosion resistance makes Cu70Ni30 (UNS C71500) mesh an ideal material for severe service conditions. Its primary applications are found in industries such as:

- Marine and Offshore:

- Seawater intake screens and strainers: Used on ships, boats, and offshore platforms to filter water while resisting biofouling and corrosion.

- Heat exchangers and condensers: The mesh is used in the construction of components that handle high-velocity seawater.

- Piping systems and valves: Critical components in marine systems where resistance to corrosion and erosion is paramount.

- Desalination Plants: Used in various parts of desalination and evaporator vessels due to its resistance to hot, saline water.

- Petrochemical and Chemical Industries: Filters and screens for handling a variety of corrosive fluids.

- Medical Equipment: Its antimicrobial properties and biocompatibility make it suitable for some medical devices and hygienic processing screens.

Mesh Weave Types

Cu70Ni30 wire mesh is available in several weave types, each suited to different applications:

- Plain Weave: The most common type, offering a simple and balanced structure for general-purpose filtration and screening.

- Twilled Weave: A stronger, denser weave that is used for high-pressure filtration.

- Dutch Weave: Used for fine filtration of very small particles.

- Welded Mesh: Used for more structural applications like grates and industrial screens.

+1 206 890 7337

+1 206 890 7337 sales1@nickel-wiremesh.com

sales1@nickel-wiremesh.com