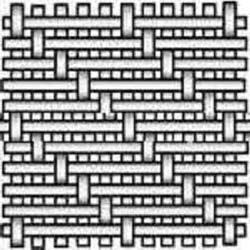

Five Heddle Wire Mesh

Key Features:

1. Excellent flow rate

2. Suitable for high mechanical pressures

3. Lightly structured mesh surface

Product Description:

Five Heddle Weave Wire Mesh is fabricated by passing every warp wire alternately up and down each single and four Shute wires and vice versa. The pattern is staggered on successive warp wires, providing a facade of parallel diagonal lines. This weave permits the use of comparatively heavier wires in the specific mesh count than recommended in other weaves. It is extensively used in supporting the heavier loads.

Five Heddle Weave Wire Mesh offers a rectangular opening. Its exclusive design supports improved drainage and flow features. The smooth surface on one side is commonly used in the petroleum and chemical filtration industries.

It is a special weaving pattern that makes it feasible to produce open meshes with high flow rates and superior mechanical stability. Simultaneously, it offers a smooth surface for easy eradication of produced cake and convenient cleaning of filter cloth.

Five Heddle Weave Wire Mesh Applications

Five Heddle Weave Mesh is used in the applications such as pressure and vacuum filters and filter candles. Commercial woven wire mesh is used in the petroleum filtration in the chemical houses. It is suitable for drum filter equipment and disc filters where the filter cake removal and cleaning is done in the continuous cycles. It is used in the mining industry, waster water processing and processed water filtration.

| Five Heddle weave mesh materials | Pure Metals | Nickel Alloys | Heating Alloys | Stainless Steels |

| Further services | Cleaning, slitting, shearing, calendaring, stretching & annealing | |||

Five Heddle Weave Wire Mesh Specifications

| Meshes per inch Warp x Weft(mesh) |

Wire Diameter (mm) | Aperture (mm) Warp x Weft |

Open Area % | Weight (kg/m2) |

| 108 X 59 | 0.160 | 0.075 X 0.271 | 20 | 1.07 |

| 110 X 60 | 0.160 | 0.071 X 0.263 | 19 | 1.09 |

| 38 X 38 | 0.150 | 0.518 X 0.518 | 60 | 0.43 |