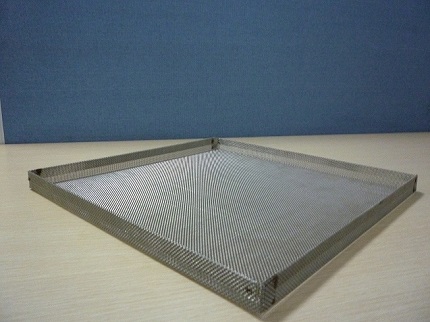

Furnace Tray

Key Features:

Enhanced performance in the severe conditions

Elastic construction to resume shape after the load is removed

High yield strength

Outstanding chemical resistance

High pressure resistance

Flame resistance

Product Description:

Furnace Tray is also called heat treatment tray. It is designed to provide maximum efficiency for heat treatment applications. It is widely used in regular heat treatments and silver sintering process of electronic components. The furnace trays are produced from the best quality heat resistant materials, such as Inconel alloys, Hastelloy alloys, Nichrome alloys or Kanthal alloys. The maximum working temperature can reach 1350℃.

Our engineers have abundant knowledge in choosing the right material and furnace tray design basing on customer’s needs. The availability of wide range of materials and forming options makes us an ideal partner to fulfill your requirements for a diverse range of industrial applications.

Properties of Furnace Trays:

Enhanced performance in the severe conditions

Elastic construction to resume shape after the load is removed

High yield strength

Outstanding chemical resistance

High pressure resistance

Flame resistance

Withstand elevated temperatures, large weight and retain versatility without deformation

Nichrome Furnace Tray is widely used for Electronic Parts Sintering Procedures. It is made of USA/EU imported material and made with advanced technique. Nichrome Furnace Tray can work for long time without deforming nor breaking in high temperature, as high as 1250oC. Upon exposure to air, the alloy forms an adherent oxide layer that prevents oxidation of the beneath metal.