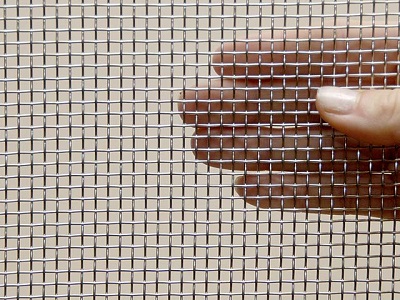

Incoloy 825 Mesh

Key Features:

1. Supreme resistance to pitting & crevice corrosion attack

2. No sensitivity to intergranular attacking conditions

3. Mesh Size: 0.2mesh/inch to 300 mesh/inch

4. Wire dia: 0.03mm to 8.0mm

Technical Data Mesh Specification ChartsProduct Description:

Incoloy 825 Mesh has firm austenitic structure, it provides enhanced corrosion resistance in the several aggressive conditions including sulfuric, phosphoric acid, nitric acid, nitrates and oxidizing salts. Incoloy 825 Mesh also has superior aqueous corrosion resistance than alloy 800. It has great mechanical properties from moderate to high temperatures. Incoloy 825 Mesh prevents attack in reducing and oxidizing acidic environments, localized corrosion and stress corrosion cracking.

Applications of Incoloy 825 Mesh:

Nuclear fuel units, seawater and desalination systems, power production plants, chemical processing, radioactive water processing and oil & gas well units

Incoloy 825 Mesh Available Sizes:

Wire diameter 0.05mm to 8mm

Aperture size: 0.05mm to 30mm

Sheet width: up to 5000 mm

Incoloy 825 Mesh chemistry:

| Ni | Fe | Cr | Mo | Cu | Mn | Ti | C | S | Si | Al | P |

| 38 – 46 % | 22 % | 19 – 23.5 % | 2.5 to 3.5 % | 1.5 to 3 % | 1 % | 0.6 to 1.2 % | 0.05 % | 0.03 % | 0.5 % | 0.2 % | 0.03 % |

Incoloy 825 Mesh Property Data:

| Density | 0.294 lb per cubic inch |

| Specific Gravity | 8.14 |

| Specific Heat | 0.105 Btu/lb/ oF at 32 to 212 of |

| Electrical Resistivity | 678 microhm-cm at 68 oF |

| Melting Point | 2525 oF |

| Poissons Ratio | 0.42 |

| Thermal Conductivity | 78.5 Btu-in/ft²-hr- oF |

| Mean Coeff Thermal Expansion | 7.8 microin./inch.-°F or 14 X 10(-6)m/m-K |

| Magnetic Permeability | 1.005 |

| Modulus of Elasticity Tension | 29.8 |