Inconel 600 Mesh

Key Features:

1.Excellent resistance to high purity water used in nuclear reactor

2. Prevents attack due to nitrides & sulfur solutions at medium temperatures

3. Mesh Size: 0.2mesh/inch to 300mesh/inch

4. Wire dia: 0.03mm to 8.0mm

Technical Data Mesh Specification ChartsProduct Description:

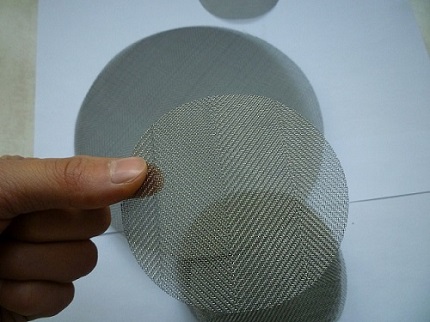

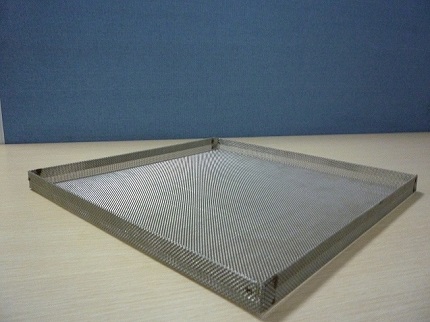

Inconel 600 Mesh (UNS N06600) is also named Inconel 600 wire mesh. We supply the product in any size and any shape, such as mesh in sheet, roll, ring shape, round shape, heat treating baskets and heat treating trays, etc.

Inconel 600 mesh is a specialized engineering material that offers excellent resistance to corrosion, heat and oxidation. It is used in the elevated temperature conditions up to 2150oF where corrosion risk due to oxidizing and reducing conditions is intense.

With its superior corrosion prevention properties, Inconel 600 Mesh is ideal for use in the nuclear steam production plants, heat processing units, polymer production, alkaline metal production, petroleum & chemical industry and furnace components.

Inconel 600 Mesh Available Specifications:

Mesh: 0.2mesh to 250mesh

Wire dia: 0.05mm to 8.0mm

Mesh width: up to 5000mm

Note: we can manufacture the mesh into any size or any shape according to customer’s requirement.

Inconel 600 Mesh Chemical Composition:

| C | Cr | Cu | Fe | Mn | Ni | Si | S |

| 0.15 % | 14 – 17 % | 0.5 % | 6 – 10 % | 1 % | Bal | 0.5 % | 0.015 % |

Inconel 600 Mesh Physical Properties:

| Density | 0.306 lb/ cubic inch |

| Specific gravity | 8.47 |

| Specific heat | 0.106 Btu/lb/ oF for 32oF to 212oF |

| Electrical resistivity | 620 micro-ohm-cm at 68oF |

| Melting Point | 2550 oF |

| Thermal conductivity | 103 |

| Mean coefficient of thermal expansion | 5.8 |

| Magnetic permeability | 1.01 |

| Modulus of elasticity tension | 31.1 |

| Reduction of area | 60 % |

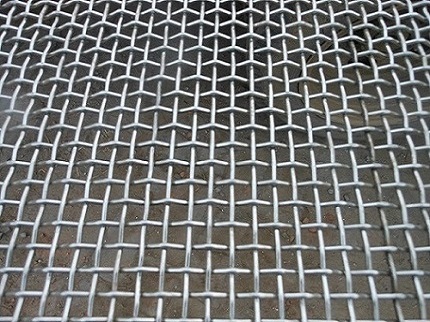

Inconel 600 wire mesh Product Pictures: