Inconel 601 Mesh

Key Features:

1. High temperature oxidation and spalling resistance

2. Great strength and prevents cracking under large stresses

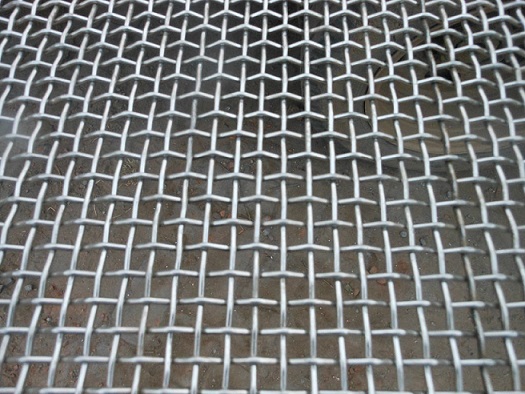

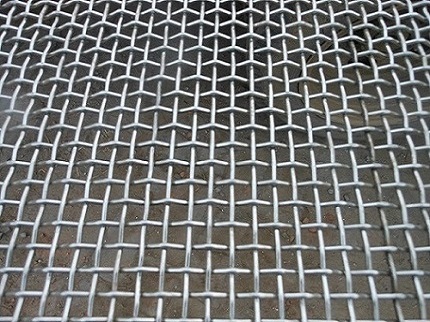

3. Mesh Size: 0.2mesh/inch to 250mesh/inch

4. Wire dia: 0.05mm to 8.0mm

Technical Data Mesh Specification ChartsProduct Description:

Inconel 601 Mesh (UNS N06601) provides excellent resistance to oxidation and aqueous corrosion in the high temperature application media. It retains mechanical properties and creep rupturing strength at the elevated temperatures up to 1260oC or 2300of. Inconel 601 Mesh is known for providing superior corrosion resistance than Inconel 600 and is commonly used in the petroleum processing units. This grade is not suggested for the applications involving sulfur based reducing environments.

Inconel 601 Mesh is heat resistant material because it prevents the formation of intermetallic embrittlement phases at the elevated temperatures. Therefore it is recommended for use in equipments for prolonged elevated temperature operations.

Inconel 601 Mesh Specifications Range:

Mesh: 0.2mesh/inch to 250mesh/inch

Wire diameter: 0.05mm to 8mm

Opening size: 0.05mm to 30mm

Sheet size: width up to 5000mm, no limit to length.

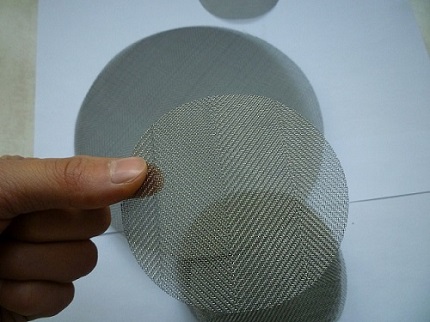

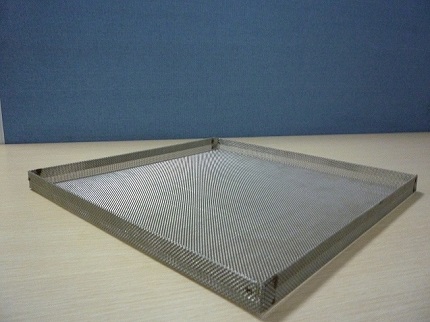

We supply Inconel mesh in any size and any shape, such as mesh in sheet, roll, ring shape, round shape, heat treating baskets and heat treating trays, etc.

Inconel 601 Mesh Properties:

- High mechanical strength and ductility

- Resists spaling, carburization and heat corrosion

- High creep rupturing strength

- Excellent corrosion resistance

- Great oxidation resistance up to 2300oFor 1260oC

Inconel 601 Mesh chemical Composition:

| Al | C | Cr | Cu | Fe | Mn | Ni | Si | S |

| 1.4 % | 0.05 | 22.5 | <=1 | 14 % | 0.3 % | 61.5 % | 0.2 % | 0.015 % |