Inconel 718 Mesh

Key Features:

1. Recommended material for use in nuclear plants and aerospace

2. Robust at elevated temperatures and resistant to extreme corrosion

3. Mesh Size: 0.2mesh/inch to 400mesh/inch

4. Wire dia: 0.03mm to 8.0mm

Technical Data Mesh Specification ChartsProduct Description:

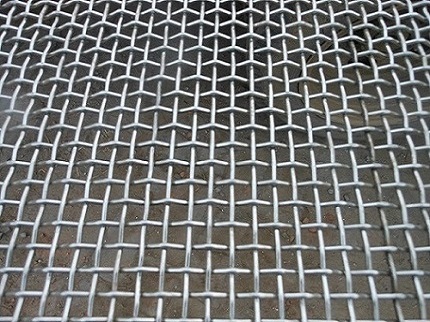

Inconel 718 Mesh (UNS N07718) provides outstanding oxidation resistance up to 1800oF. Inconel 718 Mesh has great resistance to chlorine and sulfur induced stress corrosion cracking. It also offers good resistance to aqueous corrosion, pitting and crevice corrosion.

Inconel 718 Mesh Properties:

- Prevents chlorine and sulfur induced stress corrosion cracking

- Large mechanical strength

- Elevated temperature and aqueous corrosion control

- Resistance to pitting and crevice attack

- High temperature ductility

Applications of Inconel 718 Mesh:

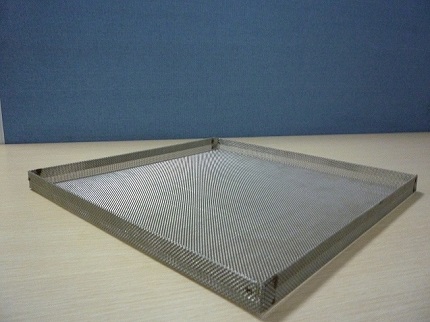

Rockets, thrust reversing devices, seawater, chemical treatment units, pollution control systems and nuclear power production reactors, cryogenic storage, turbine engines, fuel and exhaust systems

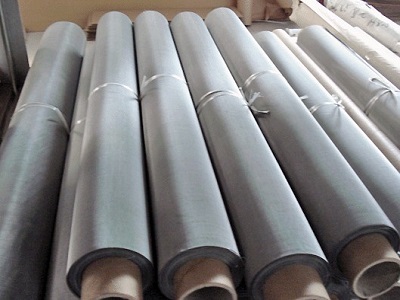

Inconel 718 Mesh Available Specifications:

Mesh: 0.2mesh/inch to 250mesh/inch

Wire diameter: 0.05mm to 8mm

Opening size: 0.05mm to 30mm

Sheet size: width up to 5000mm, no limit to length.

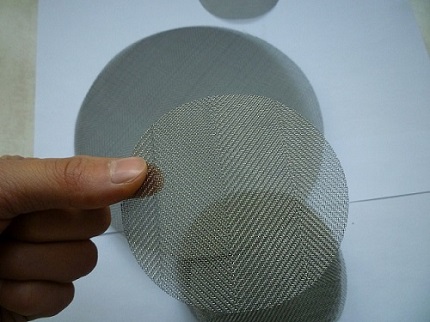

Note: We supply Inconel mesh with customized sizes and shapes, such as mesh in sheet, roll, ring shape, round shape, heat treating baskets and heat treating trays, etc.

Inconel 718 Mesh Chemistry Composition:

| % | C | Mn | Si | P | S | Ni +Co | Cr | Co | Fe | Al | Mo | Ti | B | Cu | Nb +Ta |

| Min | 50 | 17 | Bal | 0.35 | 2.80 | 0.65 | 0.001 | 4.75 | |||||||

| Max | 0.08 | 0.35 | 0.35 | 0.015 | 0.015 | 55 | 21 | 1 | 0.80 | 3.30 | 1.15 | 0.006 | 0.15 | 5.50 |

Inconel 718 Mesh Property Data:

| Specifications | ASTM B637 |

| Density | 0.296 lbs/in³ |

| Tensile Strength | 140 Kpsi* |

| Max. Operating Temperature | 1800 – 2000oF |

| Elastic modulus | 29.6 x 10 (6) psi or 208 x 10(3) MPa at 70of or 21oC |

| Coefficient of thermal expansion | 7.1 x 10(-6) per of or 12.8 x 10(-6) per oC |

| Yield strength at 0.2 % offset | 170 ksi or 1172 MPa at 200of or 93oC |

| Elongation in 2 inch | 21 percent at 200of or 93oC |