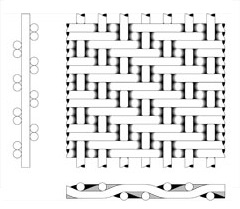

Twill Dutch Weave Wire Mesh

Key Features:

1. Excellent strength

2. Ideal for ultra-filtration applications

3. Purification of liquids and gases

3.High stability

Technical Data Mesh Specification ChartsProduct Description:

Twill Dutch Weave Wire Mesh is also called as Micromesh. It is utilized in the crucial filtration applications including very high pressure such as gas and liquid filtration.

Twill Dutch Weave Wire Mesh is made by combining the characteristics of Dutch Weave and Twilled Weave. Double layers of shute wires pass alternately up and down of two warp wires. This kind of weave can adhere under larger loads as compare to Dutch Weave with finer openings than the Twilled weave. It is utilized in applications where ultrafiltration of particles is required of diameter 2 microns.

Higher strength and finer mesh counts than general Dutch weaving styles.

Twill Dutch Weave Wire Mesh Characteristics

1. High quality results of filtration for non – sticky materials

2. Very Thick and smooth surface

3. Controlled flow rates

4. Higher strength than general Dutch weave mesh

| Twill Dutch weave mesh materials | Pure Metals | Nickel Alloys | Heating Alloys | Stainless Steels |

| Mesh size | Up to 100m x 1m (l x b) | |||

| Further services | Cleaning, slitting, shearing, calendaring, stretching & annealing | |||

Our product maintains the highest quality standards and is ISO 9001:2008 certified. All of our wire mesh products can be supplied meeting ASTM standards. It is stocked in the several specifications to assure quick delivery.

A broad range of Twilled Dutch Weave specifications are fabricated that attain the smallest monofilament filter openings with a smooth mesh surface. Great mesh stability is offered with a large material area. It is utilized for obtaining fine filtration such as fuel filtration in the severe applications and pressure sieving in hydraulic steering applications and candle filters.

Twill Dutch Weave Wire Mesh Specification

| Weave type | Mesh count | Warp wire(inches) | Shute wire (inches) |

Absolute micron rating |

Nominal micron rating |

Weight per 100 sq.’ |

| TDW | 30X250 | 0.01 | 0.008 | 110-120 | 53 | 66 |

| TDW | 80X700 | 0.004 | 0.003 | 35-40 | 25 | 25 |

| TDW | 120X400 | 0.004 | 0.0025 | 50-55 | 40 | 15 |

| TDW | 165X800 | 0.0028 | 0.002 | 25-28 | 15 | 14 |

| TDW | 200X600 | 0.0024 | 0.0018 | 30 | 20 | 10 |

| TDW | 165X1400 | 0.0028 | 0.0016 | 16-20 | 10 | 14 |

| TDW | 200X1400 | 0.0028 | 0.0016 | 12-14 | 5 | 15 |

| TDW | 325X2300 | 0.0014 | 0.001 | 8-9 | 2 | 10 |

| TDW | 400X2800 | 0.001 | 0.0008 | 6-7 | 1 | 8 |