How do high performance mesh screens improve the filter efficiency

High pressure applications create a vast challenge for air and gas micro-filtration solutions. It is because of the fact that compressed air and gases at service pressures higher than normal create a vigorous environment risk due to the contaminant concentration that is several times higher than that discovered in a standard system. For instance, the existing contaminant at 100 psi is increased 8 times that of atmospheric pressure for. A staged approach to high pressure filtration becomes a more critical consideration for system design.

Key factor for choosing a manufacturer enable to produce high efficiency and high pressure filters that meet your needs extend beyond the base service pressure limits. Features that should also be taken into account are the potential to meet the level of filtration needed, as well as the flexibility to supply a filter screen that seamlessly integrates inside your designed or current system. Your screen manufacturer should be able to meet the grade of filtration sought, where this be a series of filters configured in the existing or new systems.

Again, manufacturer should have the ability and potential to provide custom solutions to assist you in meeting your specific requirements. Following your system configuration, the solutions for existing systems will usually be inadequate or not feasible to your current system criteria. Besides to the type of filer element configured, another secondary configurable option includes the potential to customize the housing connection to match your system’s configuration. As an end user, you should have an option to specify the inlet and discharge connection types like connections into the housing design. It allows the end-user, you should have an option to specify the inlet and discharge connection types. It allows the user to specify and integrate a tailored solution instead the need to conform to what can be available.

High pressure filters are used for air and most gases including those with corrosive properties. Additionally, it is essential that the supplier have the potential to tailor that housing’s metallurgical makeup to accommodate your application. For common industrial level filtration, carbon steel can be used. For sterile applications, the housing should be comprised of stainless steel. To filter high corrosive gases, the filter screen should be made of Hastelloy C22. For your specific requirement, the manufacturer should have flexibility to offer a tailored solution that can deliver the level of filtration you require, additionally have the ability to serve in any condition in which it will be integrated, irrespective of the challenge.

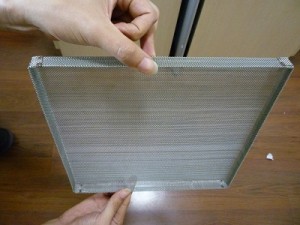

Choosing perfect filters made from Hastelloy mesh screens come in a variety of sizes. The corrosion resistant alloys are the best mesh materials that offer significant benefits such as:

- Eliminate the need of regular cleaning of filters

- Minimize the fluid exposure to workers

- Increase the service life of filter

- Considerably decrease the cost of maintenance

- Diminish the need to dispose hazardous material

High quality mesh for sintered fiber felt help to remove solid particle from fluids that pass through filter. They are made to remove the suspended particulates and particles from a continuous stream of fluid without causing a problem of clogging.