Punched special perforations

The special perforation patterns include: pressed on or drawn through round perforations, various rasp perforation, slotted bridge perforations, flapped perforations, triangular perforation, and decorative perforation and combined perforation shapes.

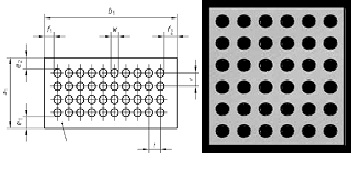

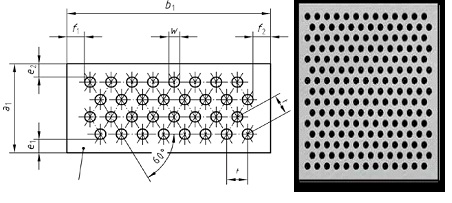

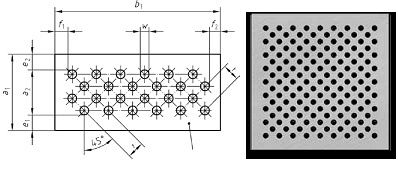

Round Perforation

The round perforations are punched in steel, high carbon steel, low carbon steel, brass and other metals. Different tools for the round perforations and moderate sizes are used.

Dimensions of perforated plates: the external dimension of round perforated plates (a1, b1, s) and width of the unperforated edges (e1, e2, f1, f2).

Round perforation in straight rows:

Open area % : A=78.5 . w2/t2

Round perforation in staggered rows:

Open area :A=90.7.w2/t2

Round perforation in diagonally staggered rows:

Open area %A=78.5.w2/t2

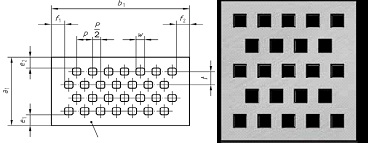

Square perforations

The square perforations are punched in the sheet steel, stainless steel, special alloys and other metal plates. Different tools for other square perforations and medium sizes are in stock.

Dimensions of perforated plates

The external dimensions of round perforated plates (a1, b1, s) and width of the unperforated edges (e1, e2, f1, f2) are to be provided on order.

Square perforation in straight rows:

Open area %A=100.w2/t2

Square perforation in staggered rows:

A=100.w2/t2

Square perforation in diagonally staggered rows:

Open area%A=100.w2/t2

Triangular perforation

The openings in the triangular perforation sheet vary from triangular to semi-elliptical shape.Simultaneously, the holes have a special conical form. The rough surface is smoothened to the finish needed using a rolling process for the triangular perforations. The hole shape is altered nominally, but the conical shape is retained.

| Material | Plate thickness | Hole width |

| Stainless steel | 0.40mm to 1.50mm or 0.16 inch to .059 inch | 0.10mm to 4 mm or .004 inch to .160 inch |

| Unalloyed steel | .50mm to 2mm or .020inch to .079 inch | .10mm to 6mm or .004 inch to .236 inch |

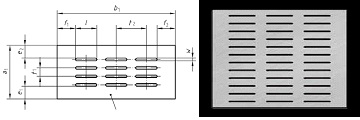

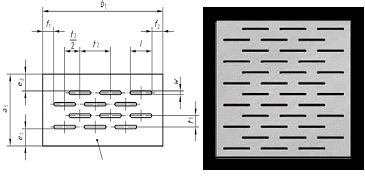

Slotted perforations

The oblong openings in the slotted perforation sheet refer that the free areas made are significantly more than the triangular perforation. On the base of demand, the slotted perforations have open areas varying from 5% to 27%.

| Material | Plate thickness | Slot perforation |

| Stainless steel | .40mm to 1mm .016inch to .040 inch | .10mm x2 mm to .80mm x 4 mm |

| Unalloyed steel | .50mm to 1 mm or .020inch to .040 inch | .004 inch x .079 inch to .031 inch x .160 inch |

A huge selection of tools is available for slotted perforations. The special tools can also be produced as per the large requirement. The standard slot pattern is round. Various other slot patterns are also provided on demand.

Dimensions of perforation plates:

The external dimensions of Slotted round perforated plates (a1, b1, s) and the width of the unperforated edges (e1,e2, f1, f2).

Slotted perforation sheet in straight rows:

A=(w.l-0.215w2/t1.t2)100

Slotted perforation in staggered rows:

Open area%=A=(w.l-0.215w2/t1.t2)100

Embossed Perforation

The combined hole shapes like perforation with embossing are employed in applications that need high pressure stability. The embossed areas reinforce thin metals with fine perforations without decreasing the free area. There are practically unlimited special criteria that can be met by us.

Embossed plates and indented surfaces

Custom embossing

By using the advanced production techniques with pressing forces about 300 tonnes, we produce embossed sheets to meet the customers needs.

The automatic equipments enable us to mention any size and shape of embossed segments. We treat various materials and on the base of the embossed shape, sheet thickness varies up to 5mm in the stainless steel. Our embossed sheets can be utilized in the wide range of applications from supporting plates, drainage grilles and industrial platforms through trays with small adhesion features for thermal processes and various other uses.

Security

Various embossed finishes meet the maximum non-slip criteria for commercial association and are utilized in the swimming pools, cooling rooms and machine walkways.

Architectural and Design

Perforated, embossed, indented and shaped stainless steel or special alloys can be utilized to introduce creativity in the life, in fact they also offer non-slip floor covering for the various demanding safety needs.

A broad range of standard embossing and indenting tools is present in our manufacturing unit.

Applications

- Building facades, interior architecture, non-slip step and floor coverings, infilling of stairs and bridge railings, shaft covers, ventilation parts, swimming pool panel,

- Ventilation grilles in silos and hopper towers, pneumatic conveyor plates, screen linings in fine coal centrifuges

- Food industry

- Process screen for starch centrifuges, drainage screens in centrifuges,mill screens, air or gas flow plates for agitator shaft and fluidized bed drying or quenching

- Chemical industry

- Centrifuge screen, such as ammonia, iron sulphate, mirabilite, washing soda, potash.

- Mill screen for comminution processes

- Preparation technology

- Plastic comminution, drying and quenching foundry sand, wood particle production for chipboard.