Uses of sintered mesh screens in industrial filters for various processes

Filters for process technology are high performance equipments that contribute in high quality ensuring the function and to a large level to increasing the service life of components, equipments and machines, longer service life, improving the quality of fluid being filtered and the feasibility of re-using the filter element together with nominal maintenance costs will decrease the production costs and the environmental impact.

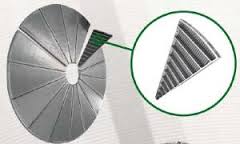

From our wide filter range, you can select between individual filter elements, filter screens are easy to clean with or without automatic backflushing. We manufacture filter elements as per customer’s specifications, they are made from sintered wire mesh for use in various applications of process technology.

The excellent properties of our high quality filter materials include high porosity with stable retention rates and a high pressure and temperature stability to an absolute filtration rating.

To choose a right filter, assess the most crucial aspects for example overall costs for maintenance and service in case of system failure. Other considerable factors are pressure drop, contamination load, filter area and cleanability of the filter material.

Our skills in filtration technology, high quality products and extensive dedication and service to the customer are the reasons we become your trusted partner.

Uses of sintered wire mesh in industrial and application filters include:

Steel plants: Process water filtration to secure the nozzles and pumps during high pressure descaling and for water conditioning for cooling of blast furnaces and rolling mills.

Paper mills: Security of all types of nozzles on paper equipments. Processing of fresh water for cooling and as process water.

Power plants: Conditioning of used water for generator cooling and sealing water filtration to increase service life of the rotary seals on turbine shafts in hydroelectric power units. Security of heat exchangers in thermal power plants.

Automotive plants: Filtration of cooling lubricants and washing fluids to increase service intervals and so economize on costs of new system. Besides, conditioning of cooling and process water for various applications in the automotive plants.

Machine tools: Improving cooling lubricant quality and hence increase their lifetime. Additionally protection of tools and hence uniform quality of components received.

Mining: Water filtration for sprinkling the shield and cutting equipments. Cooling water processing for mine ventilation. Protective filtration with backflushable block filters for the water hydraulics underground. Special screen materials for filtering HFA fluids.

Oil and gas plants: Purification of injection water, cooling water, service water, flushing water and MEG fluids in onshore and offshore plant equipments.

Seawater: Pre-processing of ballast water conditioning systems.

Water and waste water conditioning: Security filter for membrane systems for increase in lifetime of upstream candle filters for reproduction times of membranes. Industrial water conditioning in sewage treatment plants.

District heating : Protection of heat exchanger components to prevent blockages in the cooling channels.

Chemical plants: Cooling and process water filtration in various sectors of the chemical plants. Filtration of wide range of chemicals.