Which are the most economical and easiest to use Heating Mesh materials

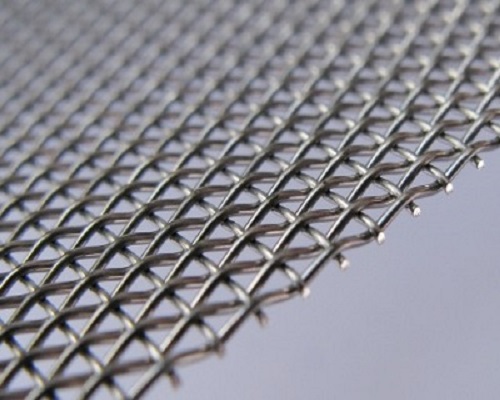

For electrical resistance heating, a wide range of materials are used as heating element such as Nichrome, tungsten and FeCrAl. They are categorized on the basis of their performance in the presence of oxygen. Some can operate at high temperatures even in the presence of oxygen and others need to be secured from oxygen based corrosion. Tungsten belongs to latter category. The heating materials can be used in air and specifically secured conditions. These materials have their function, limitations and design factors which should be considered carefully before choosing any for your application. After initial evaluation of application, user should contact nichrome mesh supplier to review the application in depth. With the changes in specifications or development of new products, a reader should contact the manufacturer of these heating mesh screens for current specifications and properties.

There are several factors which should be considered while choosing a heating element such as temperature, atmosphere, life and power. The temperature includes the service temperature. It is based on inter-connection of furnace temperature, element watt loading and the potential of the element to radiate the heat produced. An energized element will serve at a higher temperature than the surrounding ambient. Higher watt loading results into greater temperature differential or heat produced. With increase in furnace temperature, watt loading should be decreased to prevent overheating of the element.

Knowledge of service conditions is essential as with increasing temperatures, materials interact differently to different compounds. A system that operates effectively at one temperature value in air, may not perform adequately if used in a different condition at the same temperature limit. You should also be aware of the dew points and vacuum levels which can severely affect the performance of an element. For this Kanthal mesh is developed that can specifically operate successfully in vacuum, hydrogen and other reducing media.

Service life of the element is also an essential economic factor. One should take into mind if the elements serve for years. With any specific condition, the higher service temperature, shortens the life of mesh. So, for a long service life, it is suggested that the element should have a low heat temperature in context to furnace temperature. It is obtained by reducing the watt loading. The downside of this situation is that by reducing the element loading, we should add more elements to meet the heat load needs of the furnace. These additional factors result into higher initial cost and their count can be limited due to lack of space in the furnace.

Further, it is essential to consider the power requirements of a furnace. It is assessed by process temperature, magnitude of material to be heated, heating rates and furnace losses. Constrictions are applied on the magnitude of power applied to the furnace walls. These are based on element configuration, type of material and furnace temperature. Use of FeCrAl mesh and Nichrome mesh is found to be the most economical option and they are the easiest to use. For this, these materials are commonly used as heating elements such as in underfloor heating.

+1 206 890 7337

+1 206 890 7337 sales1@nickel-wiremesh.com

sales1@nickel-wiremesh.com