Why Sintered Mesh filters are recommended for vigorous application media

A variety of filter designs are used for air filtering and screening applications such as rigid wire mesh, perforated screen and sintered mesh.

Rigid woven wire mesh

We develop and manufacture woven wire mesh for filters for the removal of foreign particles in sizes ranging from 3 – 150 microns. The filter mesh is flexible and durable so it can easily adapt the equipment design. This makes it feasible to pleat the filter to widely increase its surface area for greater dirt loading capacity.

We are specialized in design and production of filter mesh for aerospace quality barrier filtration systems for helicopters. The high dirt loading capacity of these meshes makes them fit to withstand the face velocities that occur in the turbine engine and helicopter services in vigorous media.

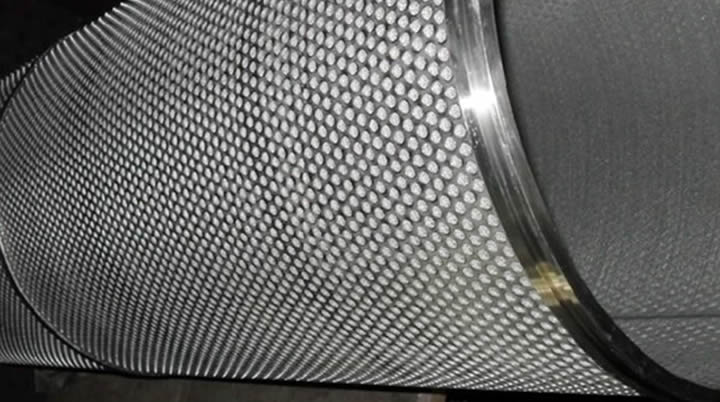

Perforated Metal Mesh

Special air intake mesh screens are made for jet engines. An aim of stainless steel filter screens is to prevent the entrance of birds and other large size debris in the jet engines. The smallest size of particle captured by perforated screen is limited around 250 microns.

Sintered Metal Media

Sintered mesh filters fabricated offer benefits over corresponding stainless steel filters. Sintered mesh is rigid that make it self-supporting and easy to cast in shape or configuration. The filter mesh comprises of small compressed spheres, developing a cleanable, depth-kind filter. Various filtering ratios are attained by altering the diameter of tiny spheres of metal. Sintered metal wire mesh filters hold less dirt than paper or steel filters however can withstand higher temperatures than paper and stainless steel.

The mesh in air filtration applications is made from aluminium, stainless steel or heavy duty metals depending on the service media. For marine systems, the mesh is specifically designed to hold particles 1 micron or smaller at pressure levels of 333 bar/ 5,000 psi.

Durable sintered mesh is fit to capture the particles for wide range from 5 microns- 250 microns. Woven wire mesh is made in weaves to fit in the various filtration applications. It is used as air intake screen and cover to secure the jet engine air intakes of fighters in storage systems.

Another type of filter in which sintered mesh used is coalesce filter to eliminate the airborne liquids like water vapour and oil mists. It is usually used in nuclear submarines.

We offer a large range of custom made mesh screens for filtration of air, fluids, lubricants, oils, fuels, water and steam. Our engineers are highly skilled in developing mesh to meet the extreme temperature, chemical and pressure needs. We have been in manufacturing the sintered mesh screens for over three decades to serve the needs of our clients in the various industries. The filters made from sintered mesh offer superior performance to traditional filters and are highly durable to handle large pressure loads. Therefore they are perfect for performance in the vigorous filtration applications.