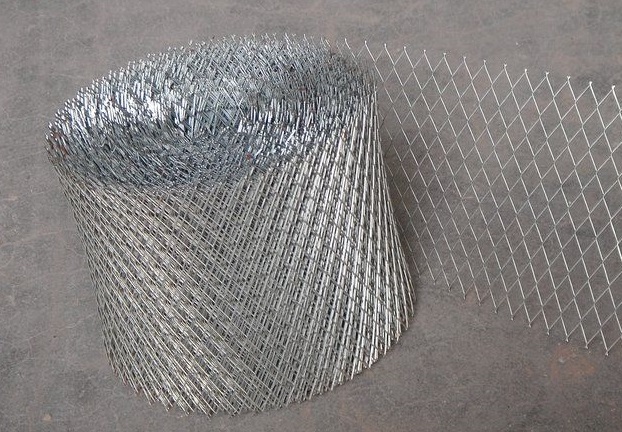

Expanded Constantan Sheet Heater

Key Features:

1. Stable electric resistance over the wide temperature ranges

2. Good resistance to general corrosion

3. High ductility

Technical Data Mesh Specification ChartsProduct Description:

Expanded Constantan Sheet Heater is made from Constantan, a copper-nickel resistance alloy that is also called as cupronickel. It offers high electric resistivity and is commonly used in resistance heating applications over a broad temperature ranges. We supply expanded constantan sheet as an electric heater.

Expanded Constantan Sheet Heater Chemical Composition

| Nickel | 60 % |

| Copper | 40% |

Expanded Constantan Sheet Heater Properties

- Excellent corrosion resistance

- Fine malleability

- Easily solderable and moldable

- High specific heat resistance

- Small temperature coefficient of electric resistivity

- Good ductility

- Excellent resistance to natural corrosion

Constantan has moderate temperature coefficient of resistance with a flatter resistance temperature curve than Manganin. It shows enhanced corrosion resistance than manganin and has limited applications in AC circuits.This thermocouple is used in the heat processing applications.

Expanded Constantan Sheet Heater Electric Resistance:

Constantan has resistance 15.94 ohm-cmil/ft that remains constant at variable temperatures therefore it is used in various appliances requiring precise resistance at the specific temperature limits.

Constantan is one of the most commonly used alloys. With its extremely high resistivity, it can also attain the suitable resistance value even in the minute grids. The temperature coefficient resistance is not large in constantan hence it is recommended over the other alloys. It is commonly used in applications where stable electric resistance is required with changing temperatures.

Constantan has high fatigue strength and large elongation capacity. The additional characteristics make it an extremely significant and suitable alloy.

Constantan Physical Properties:

| Melting Point | 1225oC to 1300oC |

| Specific gravity | 8.9 g/cc |

| Water Miscibility | Immiscible |

| Odor | No odor |

| Electric resistivity | 52 µΩ/cm at RT |

| 490 µΩ/cm at 20oC | |

| Density | 8.89 g/cm3 |

| Temperature coefficient | 400 ppm per K |

| Specific heat capacity | 0.39 J/(g.K) |

| Thermal conductivity | 19.5 W/m.K |

| Elastic modulus | 162 GPa |

| Elongation at fracture | Below 45 % |

| Tensile strength | 455 – 860 Mpa |

| Linear coefficient of thermal expansion | 14.9 x 10(-6) per K |