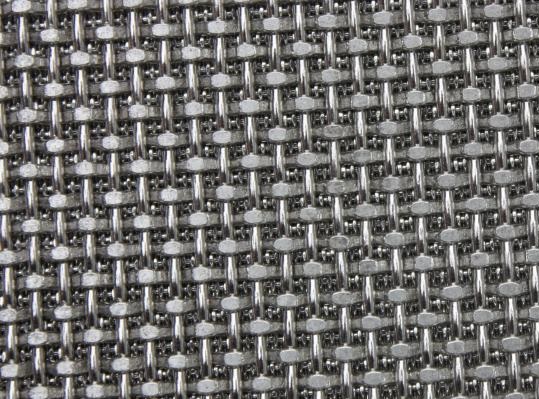

Sintered Square Woven Mesh

Key Features:

1. Proven for use in the chemical industry 2. Excellent filtering properties 3. Nominal flow resistance 4. Made from high quality industrial performance alloys

Technical Data Mesh Specification ChartsProduct Description:

Sintered square woven wire mesh is produced by sintering several layers of square plain woven wire mesh. The presence of large open area percentage in the mesh layers offers good permeability properties and small flow resistance. It is made in the various combinations of plain square woven mesh layers to obtain specific flow and filtration properties. This kind of mesh is ideally used in polymer production and different types of fluid filtration applications. It is possible to sinter multiple layers of woven mesh together to create products that are extremely thick and are used as fire and explosion resistors. In addition of thickness in inches, the mesh offers good flow properties.

Sintered square woven wire mesh characteristics

- Good mechanical strength, potential to sustain constant filter rating under large pressure applied

- Easily cleanable with different filter cleaning procedures

- Reusable

- Corrosion and heat resistant construction materials are used

- Diverse filter ratings

Sintered Square Woven Mesh Applications

1.Polymer production

3. Hydraulic Filters

4. Chromatography frits

5. Centrifuges

These excellent quality wire meshes are utilized across the world as square weave mesh for sieving and sizing applications, screen printing, filter media, laminates and support mesh for an extensive range of applications. These are used in almost all sorts of industries such as chemicals, medical, glass, ceramics, plastics, mechanical engineering, paper, environmental technology and aerospace. Sintered square woven wire mesh can be cut and fabricated into different disc, tube, filter cartridge and flat panels. Get more information about our sintered product by emailing us or speak directly with our specialist to discuss the design needs for your specific application.