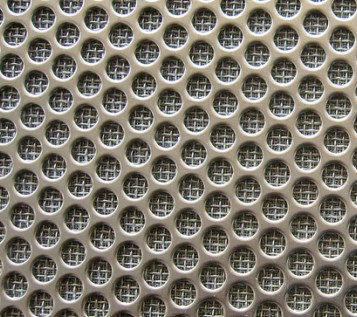

Sintered Wire Mesh with Perforated Metal

Key Features:

1. Great permeability and high strength

2. Strong Filter product

3. Withstands intense pressure and temperature environments

Technical Data Mesh Specification Charts

Product Description:

It is produced by combining single or several layers of woven wire mesh and then sintering them together with a perforated metal layer. This kind of mesh features outstanding permeability and great strength due to addition of punched sheet. The woven mesh layers comprise of a filter layer, a security layer and probably a buffer layer between the fine mesh layer and the perforated sheet. The perforated metal acts as a base and the complete structure is sintered to produce an extremely strong tractable plate. The support of a perforated sheet makes this sintered mesh extremely resistant to pressure and offers high mechanical strength. It is used in the diverse filtration applications that need to secure and maintain the filtration layer such as in oil well where filtration of extremely small particles is required under the large applied pressure.

Sintered Wire Mesh with Perforated Metal Properties

- High firmness and strength

- Precise filtration

- Fixed mesh apertures with uniform specification and without blind holes

- Excellent corrosion resistance

- Heat Resistance

Sintered Wire Mesh with Perforated Metal Applications

Commonly used in gas & liquid filtration applications, separation and recycling of solid particles, decentralized quenching in extensive heat conditions, airflow distribution, heat exchange, noise attenuation, fire protection and in aerospace, petrochemical and pharmaceutical industries.

The mesh can be customized following the filtration rating and perforated sheet’s thickness and perforation types can also be changed accordingly. To learn more about this product, please contact us.