Sintered mesh filter media for wastewater pre-treatment

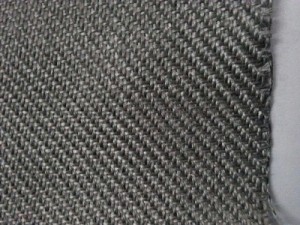

Sintered porous metal media offers long filter life through years of regular service. The solid state diffusion bonding of the sintered porous metal media resists tear, fatigue and breakthrough problems of other media. The properties of sintered wire mesh porous metal include excellent tensile strength for high differential pressures. The metal construction with welded joints and seams can withstand high temperatures.

Sintered metal media can be developed in a wide range of cartridge configurations for retrofit. 316L stainless steel and other alloys are used to meet specific needs like high temperature or chemical resistance. Its uniform porosity offers high retention efficiency. Sintered porous metal media has performed a major role from the pre-processing of waste streams, to a finishing stage filter for final solids removal.

Gas-liquid contact is an essential process operation in wastewater treatment, sintered metal spargers offer a new shape in efficient, economical performance. Besides to rugged construction and corrosion resistant characteristics, the porosity considerable enhances mass transfer. Sintered metal meshes have achieved success in applications including stripping, adsorption and direct steam injection that are found in a wide range of industries.

Sintered metal mesh is available as static or dynamic spargers. Static sparging relies of the gas pressure to develop the bubble and self release into the liquid. In dynamic cases, the bubble is developed at the surface and is sheared off by high fluid velocity.

There are two types of dynamic spargers- intrusive and non-intrusive. Intrusive spargers are inserted into a pipeline. On the other hand, non-intrusive spargers are a shell and tube design made for use in the pipeline. Non-intrusive sintered metal spargers were compared with traditional tank sparging in both agitated and non-agitated conditions. Absorption by using sintered metal media more than doubles, improving gas savings by 74%.

Standard or conventional tank sparging methods of gas include- bubble caps with large bubble propagation and low oxygen uptake- spraying and surface agitation that are energy intensive and inefficient and drilled pipe spargers that develop large, quickly rising bubbles with low contact and poor mass flow.

Applications of sintered mesh metal in wastewater settling tanks, or for steam injection to heat water. The energy saving advantages of using sintered metal mesh for steam injection when compared with a drilled pipe distributor are significant. Other applications include:

- Oxygen injection for BOD and COD

- Oxygen stripping

- pH adjustment and control neutralizing alkaline solutions

- Prevention of steam hammer

- Volatile stripping- elimination of Volatile organic compounds from waste streams

- Inclusion of oxygen to oxygen depleted water before the discharge from a plant site, sparging into basins to maintain aerobic bacteria activity.

- Inclusion of oxygen to O3 to purify and supply oxygen to municipal water supplies

- Ozone treatment

Waste water COD reduction

The filtration process to capture tails from the crystallizer above 2 micro-m and return back to the crystal separator for zero waste operation and nominal waste water contamination. Process conditions needed all 316L SS materials of use. Sintered metal tubular backwash filter mesh met process requirements regarding flux, delivered suitable filtrate quality and serves with automatic backwash cycling.