Sintered and Decorative Mesh: Their role in industrial and public sector

Sintered Mesh: Its properties and uses

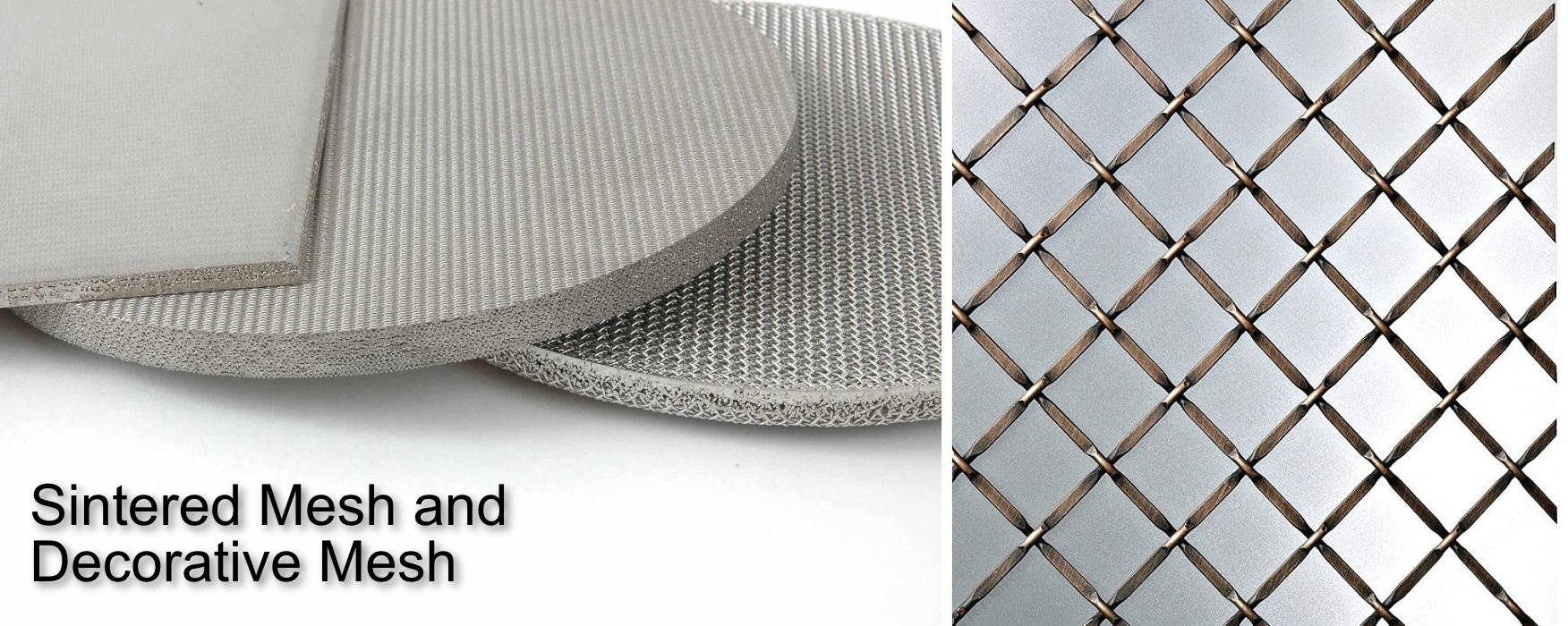

Multiple layers of woven wire mesh are bonded together under heat and pressure to form sintered mesh. Sintered mesh is widely used for filtration purpose as it can’t be corroded easily. It has several advantages over other materials such as

- It can be used in high pressure and viscosity conditions.

- It is highly durable and strong.

- It is hard to deform due to multiple layers.

- It has high heat resistance of up to 480°

- It can be easily stretched, welded, punched and cut.

- It has stable filter rating.

Sintered mesh is used in various fields such as Pharmaceutical industries, Petrochemical industries, Aerospace industries etc. It has a variety of uses such as

- Filtration of various liquid and gas particles.

- Separation of solid particles.

- Control of air flow.

- Reduction of noise.

- Limiting the current.

- Heat enhancement.

- Cooling in extremely high temperature.

Plain weave sintered mesh is widely used for filtration applications due to its excellent permeability characteristics and low resistance to flow. It is prepared by sintering of many layers of plain weave square woven mesh. It is also used for polymer production. It can be formed into various designs of tubes, flat panels, discs and filter cartridges.

Another type of sintered mesh is Dutch woven sintered wire mesh. It is prepared by vacuum sintering, pressurizing and rolling of 3 layers of plain Dutch woven wire mesh and 3 layers of stainless steel mesh. It is used in several applications such as

- Laboratory fluid bed

- Coolers

- Driers

- Powder transport

- Liquid filtration

- Gas filtration

- Pharmacy filtration

- Chemical filtration

- Laboratory filtration

Decorative Mesh: Its properties and uses

Decorative mesh can be prepared from various types of woven, perforated, expanded and assembled mesh. Decorative meshes can be formed by hand or by industrial machines. Mesh for interior decoration is generally hand woven as it has more traditional feel as compared to machine woven mesh. Strands of wire are woven together as clothes are woven to prepare a decorative woven mesh. Decorative mesh is widely used in homes, vehicles, manufacturing industries, fashion industries etc. It can have a variety of properties depending upon its shape and size. Decorative mesh can be as fine as a cloth and can be used for manufacturing clothes. This type of fine mesh can be used in architecture and art as screens and shades of various types.

Another type of decorative mesh is a welded wire mesh panel that is used in industrial applications such as cages for animals and fencing. Welded wire mesh is economical and modern product. However, woven wire mesh gives more attractive appearance as compared to welded one. There are various patterns and styles by which woven mesh is prepared due to its high architectural and interior decorative use. Two common types of woven wire mesh are twilled Dutch weave and reverse Dutch weave. Decorative mesh can also be prepared by using a combination of different materials for more attractive appearance.