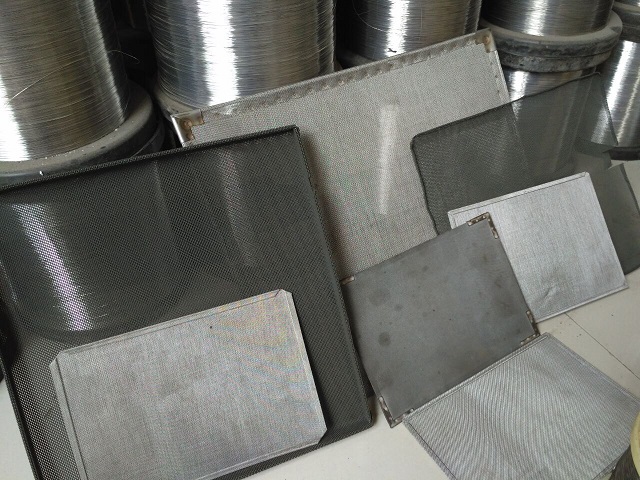

Applications of advanced mesh materials

High service mesh elements are used when the operation temperature limits increases beyond the capacity level of conventional filters and where an alternative media is required. Our mesh elements are highly resistant to a wide range of chemical media at high temperatures even also to sulfuric acid and nitric acid. They can be used for thousands of hours in steam and high pressure water without considerable loss in their properties.

Increased lifetime

Our mesh products are strong, stiff and hard made from high quality super metals and alloys offering good friction and wear characteristics. Therefore they are considered as universal products for filtration media. They are perfectly suitable for applications where high temperature or vigorous environments totally damage the ordinary elements.

The range of mesh fabrics is expanding at vast rate. Our specialists assist you in choosing a suitable mesh material for your application. So consult with our sales departments for the availability of current materials. We have developed a great range of fabrication capabilities suited for mesh products.

Uses of filter mesh elements

Fuel pump: Mesh filters are used in high temperature conditions in the hot fuel mixtures. They offer suitable fatigue resistance in variable stress conditions and hence has a more limited service time. Mesh fabrics made from super metals and alloys such as Tungsten wire mesh offer the excellent corrosion resistance.

Biodiesel fuel filtration: Over the time, biodiesel popularity is increasing at the wide level for offering several advantages. Although the ordinary fuel filters fail soon in Biodiesel, using high quality mesh filters offers higher resistance to Biodiesel and hence increases service life of a fuel filter.

High Pressure liquid Chromatography columns: A chromatography column often includes a security filter on the bottom of the column. Woven mesh elements offer outstanding resistance to a great range of organic and inorganic chemicals and hence are fit for various solvents used in HPLC including sulfuric acid and nitric acid.

Battery – Different types of materials are used in battery to separate layers in a battery. The spacer materials should attain supreme chemical resistance to acidic compounds and solutions used in the battery. Thickness and controlled porosity are also essential properties. The mesh materials can be developed about 50 microns. Additionally they do not shed and prevent premature battery failure. Our mesh elements are introducing a new generation of high technology filtration solutions with compact size and high power density and excellent reliability.

Membrane support

Woven wire mesh products are widely used in different applications where delicate membranes are secured and supported. In few cases, membrane functionality is improved by using woven mesh. For instance fuel cells. Standing service temperature limit varies up to 150oC. The applications demanding high performance and efficiency use woven mesh supports for membrane to keep consecutive layers separate and prevent cracks. As the overall size of the fuel cell is essential, membranes and spaces are made very thin.