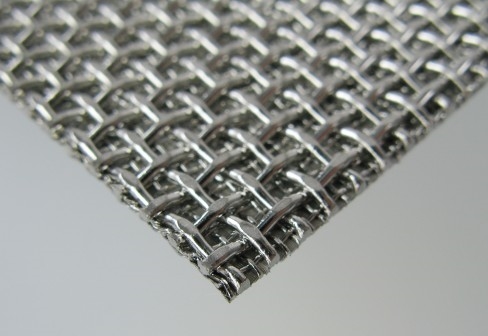

Sintered Wire Mesh

Key Features:

1. High mechanical strength with suitable fabricability

2. Strong and secured mesh

Technical Data Mesh Specification Charts

Product Description:

Sintered Wire Mesh involves the thermal processing of mesh to realign and permanently bond all the wires of mesh where they intersect or touch each other by heating at a constant pressure in a specific media for a particular time duration. The process creates a stable and secured mesh that can be utilized for filtering and high pressure applications. It is made in the single or multiple layers.

In Mesh Sintering, temperature and atmosphere have a significant role to protect and connect intersection wires. A high grade stability and security is received in a woven mesh that is ideal for deep drawing and prevents the risk of migration of wires.

Properties of Sintered Wire Mesh

Sintered wire mesh offers several advantages when compared to traditional wire cloth:

- Diffusion bonded wire mesh can be produced in single or multiple layers. Multiple layer assembly offers enhanced mechanical features for filters and hard condition applications.

- Bonded sintered mesh is stable, ideal for mesh with large percentage of open area or that creates a secured pore size.

- Sintered mesh is an easily fabricated stable and strong product. It can be produced as a depth filter media, offering outstanding filtration characteristics. It is an ideal material for products that need controlled permeability.

- Easy cleaning and reusing for several applications.

- Diffusion bonding locks all wires in mesh, preventing movement of wires and improving the mesh stability. It can be utilized in small components and special shapes without losing shape or loose wires. On the other hand, traditional wire mesh can become ineffective and loosen over the period.

Sintered mesh is introduced in the several ranges of micron rating, mechanical characteristics and alloys. Besides of standard products, we provide custom weaves in an extensive range of alloys and materials and layering configurations to offer a product that meets your specific specifications.

Single Layer Laminate Series: Confirms that all warp and shute wires are locked protectively. It also permits quick in-depth drawing and forming.

Multiple Layer Laminate Series: Varying from two layers to above 25 individual layers of wire mesh bonded to produce an exclusively integrated structure.

Custom Design Laminates: It is a layer of material made by using woven mesh, perforated sheet and foils to produce hybrid materials that are lightweight and flexible.

We can supply finished filter elements, custom shapes, weld rings and end fittings for your component, offering a production ready mesh for your applications.